A wide range of decking solutions is available today for aluminum fixed and floating dock systems. Over the past two decades, materials have evolved significantly, driven largely by the rapid development of composite and polymer-based products, which now represent a substantial share of the global marine infrastructure market.

Today, more than 80% of fixed and floating dock installations rely on a limited number of decking material families. While each offers specific advantages in terms of barefoot comfort, aesthetics, maintenance and initial cost, each also presents inherent limitations that can materially affect long-term performance, safety, and total cost of ownership.

This article is written specifically for public-sector owners, port authorities, and infrastructure decision-makers seeking decking solutions that are:

- inert and dimensionally stable

- non-combustible or exhibiting limited flame spread characteristics

- low or maintenance-free

- capable of predictable and repeatable performance over multiple decades

Rather than promoting a single material, the objective is to provide a clear comparative framework to support informed decisions for both fixed piers and floating dock systems.

Lifecycle Performance in Marine Environments: A Strategic Investment Perspective

While initial capital cost often influences procurement decisions, experienced infrastructure owners understand that true value is measured over decades, not at purchase.

In marine environments defined by high heat, humidity, salt spray, and chloride exposure, decking systems operate under constant environmental stress. For public marinas, resort waterfronts, and pedestrian bridges, expected service life typically ranges from 30 to 75+ years depending on asset class and regulatory requirements.

Materials that require frequent maintenance, board replacement, fastener tightening, refinishing, or unplanned repairs introduce hidden costs that directly impact:

- Operational budgets

- Asset valuation

- Insurance risk exposure

- Guest experience and brand perception

- Long-term return on investment

What may appear cost-effective at installation can become significantly more expensive when lifecycle maintenance, downtime, and liability risk are fully considered.

For decision-makers overseeing large marina portfolios, hospitality assets, or public waterfront infrastructure, key evaluation criteria extend beyond aesthetics and comfort. They include:

- Fire safety and combustibility classification

- Structural stability under thermal and environmental loading

- Cold- and heat-performance reliability

- Resistance to creep and long-term deformation

- Predictable maintenance cycles

- Total lifecycle cost

In this context, decking material selection becomes a strategic asset decision, not merely a construction choice. Selecting systems with stable mechanical behavior, minimal maintenance requirements, and documented long-term durability reduces lifecycle risk and protects capital over multi-decade ownership horizons.

The Two Main Families of Composite Decking

Composite decking products used in marina and pedestrian environments generally fall into two distinct families, based on the polymer matrix used to bind the reinforcing fibers. Although both are often marketed under the generic term “composite decking”, their long-term behavior differs in important ways.

Composite Decking Based on Polyethylene (PE) or Polypropylene (PP)

Composite decking systems based on polyethylene (PE) or polypropylene (PP) have long been used in residential applications such as terraces and private decks. In recent years, they have also been introduced into certain floating dock installations, primarily due to their relatively low routine maintenance requirements and wood-like aesthetic appearance. These systems are often selected for comfort-driven environments where barefoot usability and visual appeal are key considerations.

As thermoplastic-based materials, PE/PP composites exhibit temperature-dependent mechanical behavior. Under elevated temperatures, particularly with direct solar exposure, the elastic modulus decreases, resulting in increased flexibility and time-dependent deformation (creep) under sustained loading. While this behavior can be managed through appropriate engineering and detailing, it requires careful evaluation in commercial dock and marina applications where structural reliability and long-term performance are critical.

PE/PP composites also have relatively high coefficients of thermal expansion (Stanford Advanced Materials), typically four to eight times higher than aluminum when installed over aluminum dock framing. In floating dock systems, where structural movement from wave-induced torsion and flexure is inherent, thermal expansion must be properly accommodated through adequate expansion gaps and flexible fastening systems. Failure to properly account for thermal movement can introduce additional stresses in fasteners and connection points over time.

Additionally, as thermoplastic materials, these composites remain combustible and are inherently susceptible to long-term creep and reduced stiffness at elevated temperatures. For higher-demand environments, particularly public or commercial floating aluminum dock structures, designers must carefully assess thermal movement, fastening strategy, fire exposure risk, and long-term deformation characteristics to ensure safe and durable performance.

Composite Decking Based on PVC and Fibres

PVC-based composite decking generally offers improved dimensional stability, reduced moisture sensitivity, and better control of thermal movement and creep compared to PE/PP-based systems. Its wood-like appearance makes it visually appealing for marina and pedestrian environments, and it is often positioned as a higher-end option within the composite decking category.

Some PVC-based composite products achieve fire performance classifications such as UL 94 V-0, indicating that the material does not sustain combustion once the ignition source is removed. Nevertheless, despite this improved fire behavior relative to other polymer composites, PVC decking remains a polymer-based material and does not provide the inherent non-combustibility or long-term structural predictability of metallic or mineral decking systems used in public infrastructure.

PVC-based composite decking exhibits thermal expansion coefficients approximately two to three times higher in case of using an aluminum dock frame. While significantly more stable than PE/PP composites, PVC systems still require careful expansion detailing and flexible fastening strategies, particularly on docks, where aluminum offers unmatched dimensional stability, zero creep, and predictable long-term performance.

Key Takeaway on Composite Decking

Although PE/PP and PVC-based composites differ in formulation and relative performance, both families share inherent limitations:

- combustibility

- time-dependent deformation

- sensitivity to temperature extremes

- limited documented service life in high-duty public infrastructure

Composite decking, regardless of formulation, can perform effectively in pedestrian applications when support spacing, fastening systems, and thermal expansion joints are properly engineered, detailed, and installed. These systems can offer low routine maintenance, good comfort underfoot, and appealing aesthetics. However, fire performance should be carefully evaluated, particularly for PE/PP-based composites.

Polypropylene (PP) Deck Tiles

Polypropylene deck tiles are lightweight, modular systems typically used for temporary or low-duty dock applications. Their low costs and thermal mass provides acceptable barefoot comfort under sun exposure, particularly in warm climates.

However, polypropylene is a combustible thermoplastic with limited fire resistance and reduced impact performance at low temperatures. Long-term durability is highly dependent on UV stabilization, formulation quality, and environmental exposure.

It should be noted that certain polypropylene (PP) tile systems rely primarily on corner clips with limited mechanical fastening to facilitate low-cost installation. While economical, this attachment method has demonstrated performance limitations on aluminum floating dock applications. Repeated torsional and flexural movements induced by wave action can contribute to progressive disengagement, reduced clamping force, and localized failures over time if not properly engineered and secured.

Customization further weakens these systems. Cutting tiles to accommodate widths, angles, or non-orthogonal layouts compromises integrated stiffeners and clipping features, significantly reducing fixation capacity.

Conclusion: Polypropylene deck tiles are suitable for light-duty, easily replaceable surfaces and are not appropriate for long-life public marina infrastructure.

Extruded Aluminum Decking

Extruded aluminum decking represents a fundamentally different approach. As an engineered, metal-based system, it is specifically designed for high-duty marina, dock, and pedestrian bridge applications.

While bare aluminum has higher thermal conductivity than polymers, modern extruded profiles incorporating ribs, teeth, and textured anti-slip surfaces, combined or not with appropriate coatings, can provide acceptable barefoot comfort while delivering superior structural performance.

Aluminum is:

- inherently non-combustible

- immune to rot, moisture, and UV degradation

- highly impact-resistant, including in sub-zero conditions

- unaffected by creep or long-term deformation

With proper detailing, extruded aluminum decking routinely exceeds pedestrian bridge and dock design code requirements, often achieving service lives well beyond 75 years with minimal maintenance. Read about the rise of aluminum docks and why so many people prefer it in our related feature.

Wood-Based Decking Options

IPE Exotic Hardwood

IPE is a dense tropical hardwood traditionally used in high-end waterfront and architectural applications. It provides excellent initial barefoot comfort, high natural durability, and exceptional mechanical strength for a wood-based material. Among timber species, IPE also exhibits favorable fire behavior, characterized by low flame spread and a tendency to char rather than actively propagate fire.

However, IPE remains a high-cost material and is increasingly subject to scrutiny regarding traceability, sourcing practices, and long-term environmental sustainability, factors that can complicate its use in public infrastructure projects.

White Ash Thermowood®

Thermally modified White Ash improves dimensional stability and decay resistance without chemical preservatives and offers good barefoot comfort with a natural appearance. Originated in Finland in the early 1990s as a sustainable, chemical-free alternative to tropical hardwoods (Canada Wood Preservation Association). However, thermal modification reduces mechanical strength and impact resistance, particularly in cold climates. Like all wood-based materials, it remains combustible and maintenance-dependent. Its long-term performance record in high-duty public infrastructure remains limited currently.

Treated Softwood

Pressure-treated softwood is commonly selected as a cost-effective solution for budget-constrained projects. While it typically offers acceptable initial barefoot comfort, it is susceptible to warping, checking, splintering, and accelerated deterioration in marine and high-moisture environments. The need for frequent maintenance, combined with a relatively short and unpredictable service life, significantly limits its suitability for public marina infrastructure and other long-term, high-use applications.

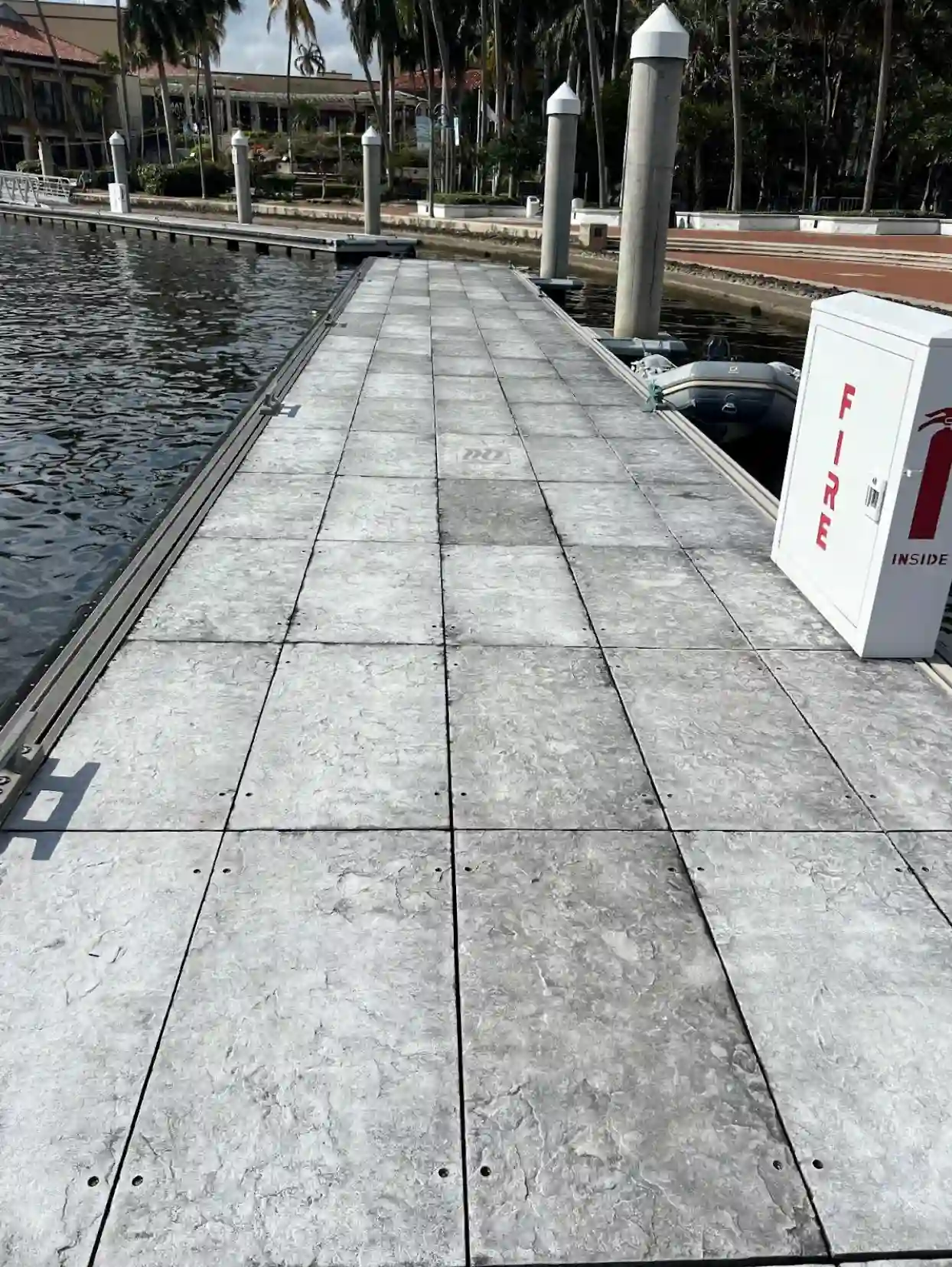

Concrete Deck Tiles and Pavers

Concrete deck tiles offer excellent fire performance and long-term durability in fixed, ground-supported applications. However, their high thermal mass results in poor barefoot comfort under sun exposure, and their weight and brittleness limit their suitability for floating docks or remote installations.

Concrete is best reserved for fixed, urban piers with direct ground support and easy maintenance access.

Decking Selection: Floating Aluminum Docks vs Fixed Aluminum Piers

Floating Docks

Floating docks are highly sensitive to dead load, dynamic movement, and fatigue. Decking must therefore be lightweight, non-combustible, dimensionally stable, and low maintenance to preserve buoyancy efficiency and long-term structural integrity.

Extruded aluminum decking remains the benchmark solution for floating dock systems, offering exceptional structural predictability, durability, and minimal lifecycle risk. While surface coatings can enhance aesthetics, they may introduce additional lifecycle considerations, as coatings can weather, fade, chip, or require periodic refinishing. In contrast, a properly finished aluminum surface, such as clear anodized, maintains its appearance without repainting and offers excellent durability in marine environments. That said, even clear anodizing preserves the natural metallic character of aluminum, which may still present a more architectural or contemporary look rather than a traditional wood aesthetic.

Fixed Piers

Fixed piers provide greater tolerance for decking weight; however, fire safety, long-term durability, storm resilience, and pedestrian comfort remain critical design considerations.

Aluminum decking remains the leading solution in terms of structural durability, dimensional stability, and lifecycle performance. Its aesthetic, however, is often perceived as contemporary and more architectural compared to the warmer appearance of natural or wood-look materials, which may not align with all design visions or traditional waterfront environments.

Concrete decking can be suitable in ground-supported applications where additional weight is not a constraint and barefoot comfort is a secondary consideration.

In southern and hurricane-prone regions, another critical factor is uplift resistance. Fixed piers are subject to significant wind and hydrodynamic uplift forces during storm events. The attachment system between the decking and supporting structure therefore becomes paramount. Inadequate fastening or detailing may lead to partial or total deck failure under extreme uplift pressures. Unlike floating docks, where buoyancy elements can help absorb and redistribute loads, fixed structures rely entirely on robust mechanical anchorage to resist storm-induced forces.

Final Takeaway for Decision-Makers

For public marinas and critical waterfront floating infrastructure seeking maximum safety, durability, and predictable performance over multiple decades, extruded aluminum decking clearly stands apart. It is the only decking solution that consistently satisfies fire safety requirements, aggressive marine exposure demands, and long-term structural performance objectives, across both floating dock systems. For fixed piers aluminum and concrete are another possibility based on maximum safety, durability, and predictable performance over multiple decades.

When properly engineered and manufactured, aluminum decking delivers the lowest lifecycle risk and the strongest long-term return on capital investment. Its non-combustibility, dimensional stability, impact resistance, and minimal maintenance profile make it particularly well suited for public infrastructure, institutional assets, and large marina portfolios.

For High-End Marina & Resort Projects

In luxury or architecturally driven waterfront developments, alternative materials may be considered where aesthetics and tactile experience are primary drivers:

- IPE exotic hardwood remains a premium option with a long and well-documented track record of success in high-end marine applications.

- White Ash Thermowood®, while newer to the North American market, has been used in Scandinavian countries since the early 1990s and can provide an attractive, natural alternative when properly detailed and maintained. (Canada Wood Preservation Association)

- PVC-based composite decking (PVC + fibres) may offer a balanced solution where low routine maintenance, wood-like appearance, and dimensional stability are desired within moderate structural demand environments.

For Comfort-Driven, Light-Duty Applications

- Polypropylene (PP) deck tiles

- Composite decking based on polyethylene (PE) or polypropylene (PP)

These systems can be appropriate in lower-cost, light-duty, comfort-driven environments where barefoot usability and visual appeal are prioritized. However, they should generally be reserved for applications with limited structural demand and lower lifecycle performance expectations.

Materials Requiring Careful Consideration

Treated softwood decking is generally not recommended for aluminum dock structures. Its service life is often significantly shorter than that of an aluminum frame (sometimes 25% or less) resulting in multiple replacement cycles over the marina’s lifespan. Repeated removal and re-fastening can lead to excessive drilling in aluminum stringers, potentially affecting long-term integrity and maintenance costs.

Concrete deck tiles and pavers have been used in certain fixed, ground-supported pier applications. However, their high dead load makes them unsuitable for floating docks, where increased buoyancy requirements directly impact system cost and performance. Concrete may be appropriate on fixed piers where weight is not a limiting factor and fire performance is a priority.

Strategic Perspective

Decking selection is not merely a finish decision; it is a structural, financial, and risk management decision.

For floating aluminum docks and long-life public waterfront infrastructure, extruded aluminum decking remains the most technically robust and financially predictable solution available today.

For architectural or hospitality-focused developments, select alternatives may be appropriate, provided their lifecycle implications, maintenance demands, and structural limitations are fully understood.

Final Takeaway for Decision-Makers

For public marinas seeking maximum safety, durability, and predictable performance over multiple decades, extruded aluminum decking stands apart as the only solution that consistently satisfies fire safety requirements, environmental exposure demands, and long-term infrastructure objectives, across both floating and fixed waterfront structures.

When properly designed and manufactured, aluminum decking delivers the lowest lifecycle risk and highest return on long-term public investment.

Comparative Decking Materials – Public Marina Applications

| Material | Price Level | Barefoot Comfort (Heat) | Slip Resistance | Fire Performance | Cold Weather Impact | Durability / Service Life | Maintenance | Suitability – Public Marina |

| Polypropylene Deck Tiles | Medium | Excellent | Good (textured) | Combustible | Reduced impact resistance in cold | Low–Moderate (UV dependent) | Low–Moderate | Modern appearance, lightweight, requires through-fastening, light-duty only & fire considerations |

| Capped Composite

(PE/PP + Wood Fibres) |

High | Good | Very good | Combustible | Reduced impact resistance | Moderate (creep & thermal expansion) | Low | Low maintenance, specialist install, non-structural use & fire considerations |

| Composite PVC + Fibres | Medium | Good | Very good | Self-extinguishing but combustible | Moderate | Moderate | Low | Modern aesthetic, low maintenance, mid-range cost

(comfort-driven applications) |

| White Ash Thermowood | High | Very good | Good

(when new) |

Combustible | Brittle at low temperatures | Moderate | Moderate | Premium aesthetic, environmentally friendly, limited marina track record (maintenance considerations) |

| IPE Exotic Hardwood | High | Very good (initially) | Good (degrades when wet) | Combustible (strong fire behavior for wood) | Variable | Moderate | High | Premium appearance, suited primarily for high-end projects |

| Treated Softwood (Natural Finish) | Low | Good | Fair–Good | Combustible | Variable | Low–Moderate | High | Economical purchase, short service life, high upkeep, combustible material |

| Concrete Deck Slabs / Pavers | High | Poor (heat retention) | Good (textured finish) | Non-combustible | Brittle | High (fixed, ground-supported only) | Low | High weight, suited for fixed docks, low comfort, high cost |

| Extruded Aluminum Decking | High | Good (engineered finish) | Excellent (anti-slip ribs) | Non-combustible | Excellent | Very high (75+ years) | Very low | Non-combustible, marine-grade, lightweight, long lifecycle |

Key Takeaway: Extruded aluminum decking is highly recommended for public marina applications due to fire performance, durability, and low maintenance.