Start your Aluminum Structure Project

Durable

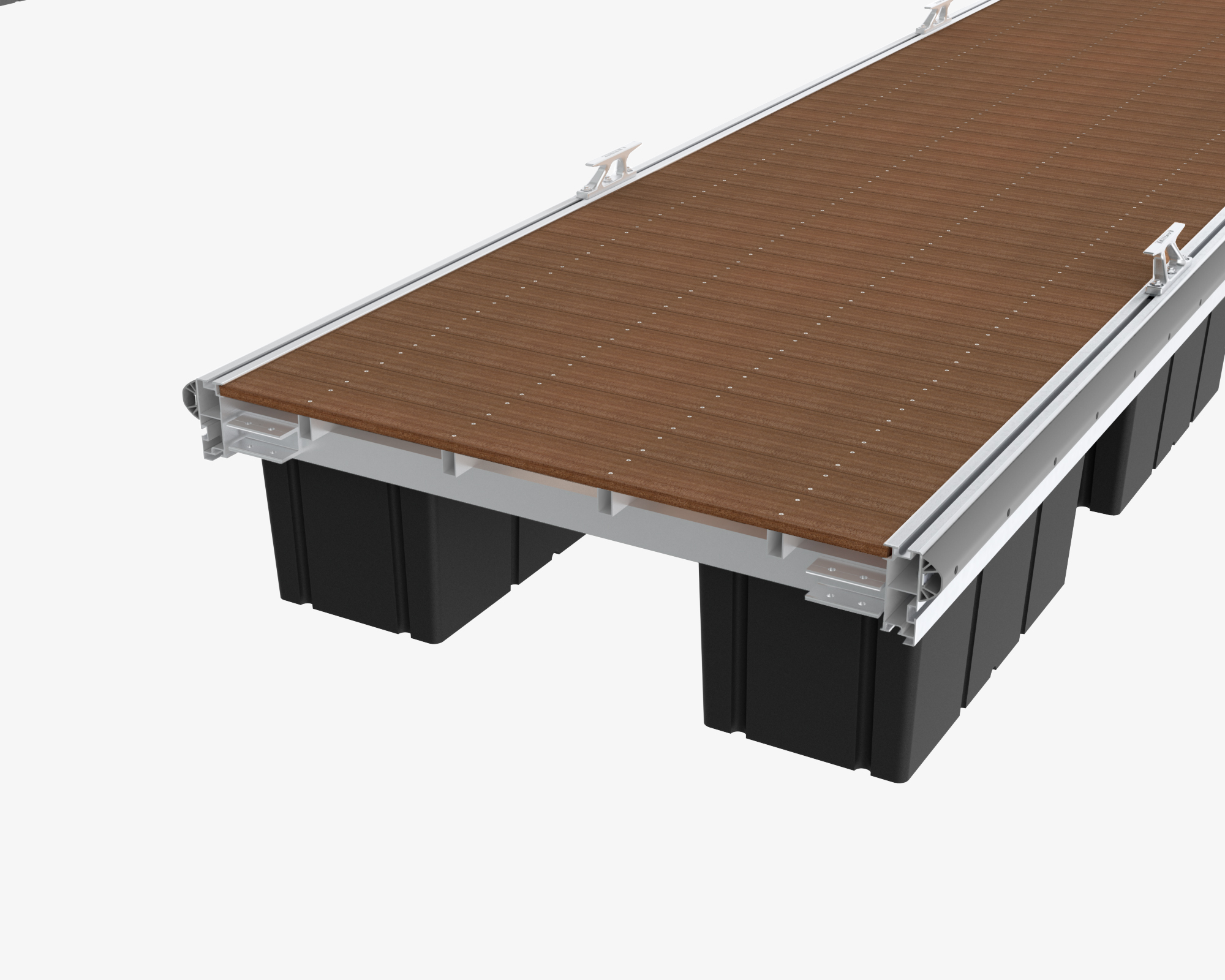

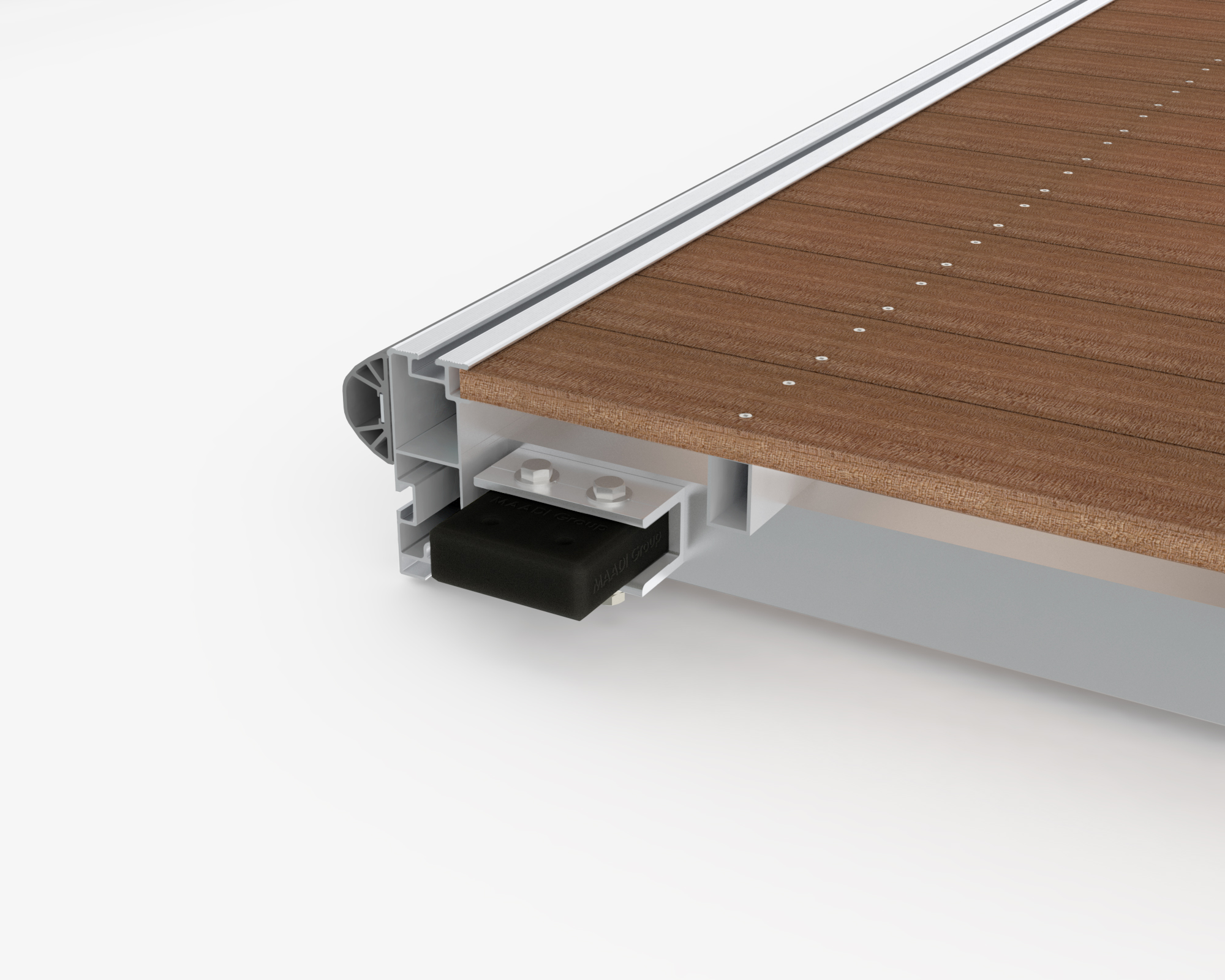

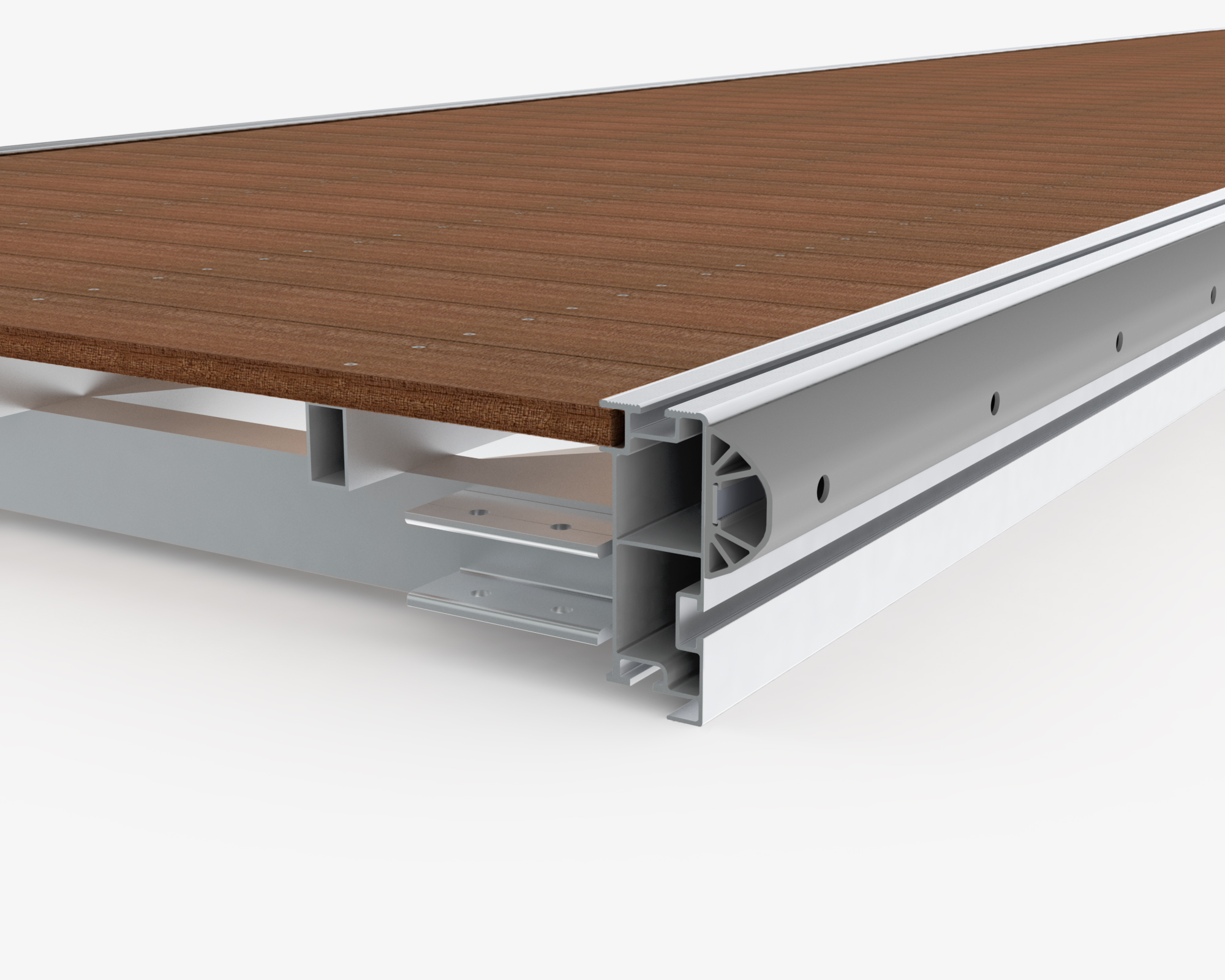

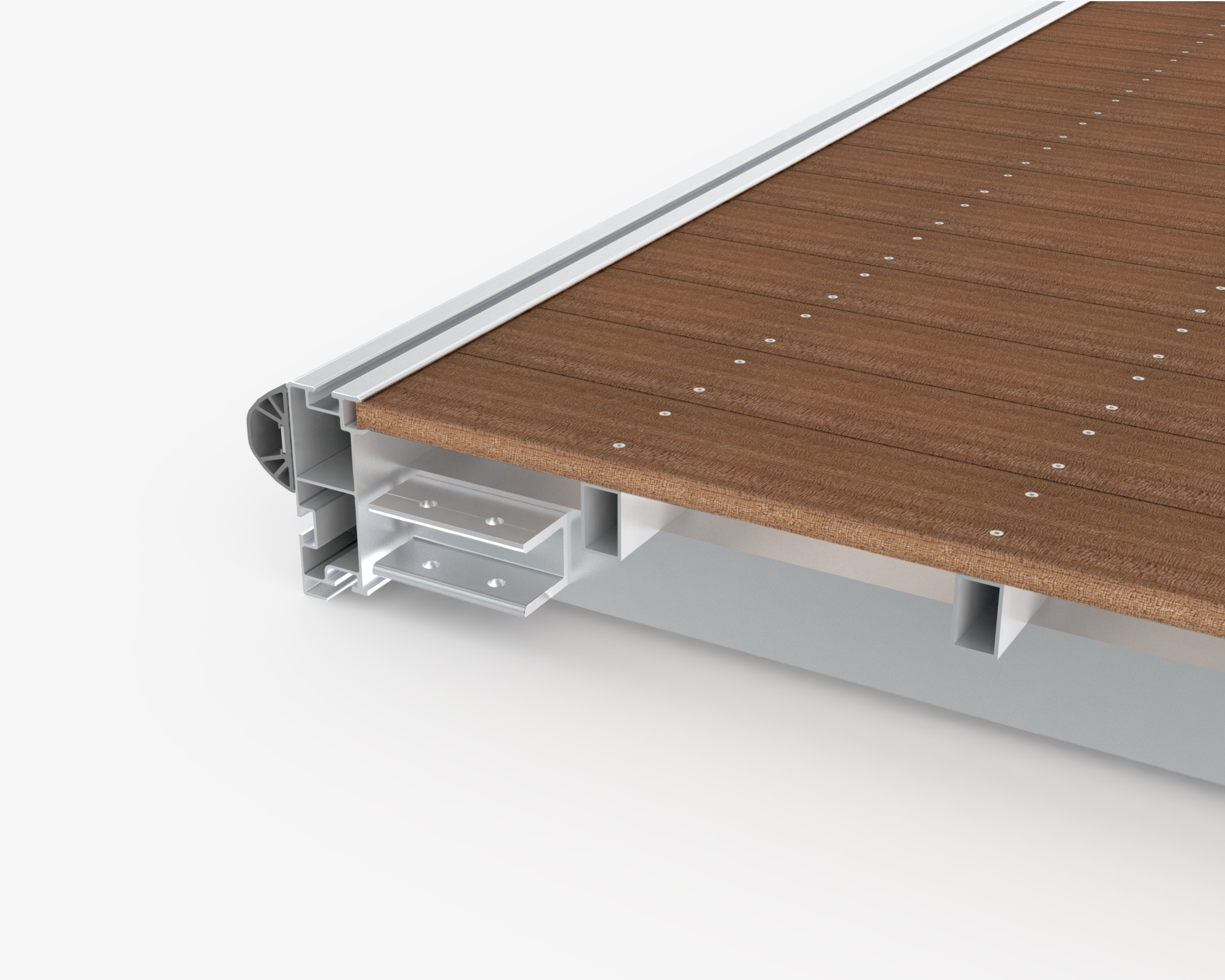

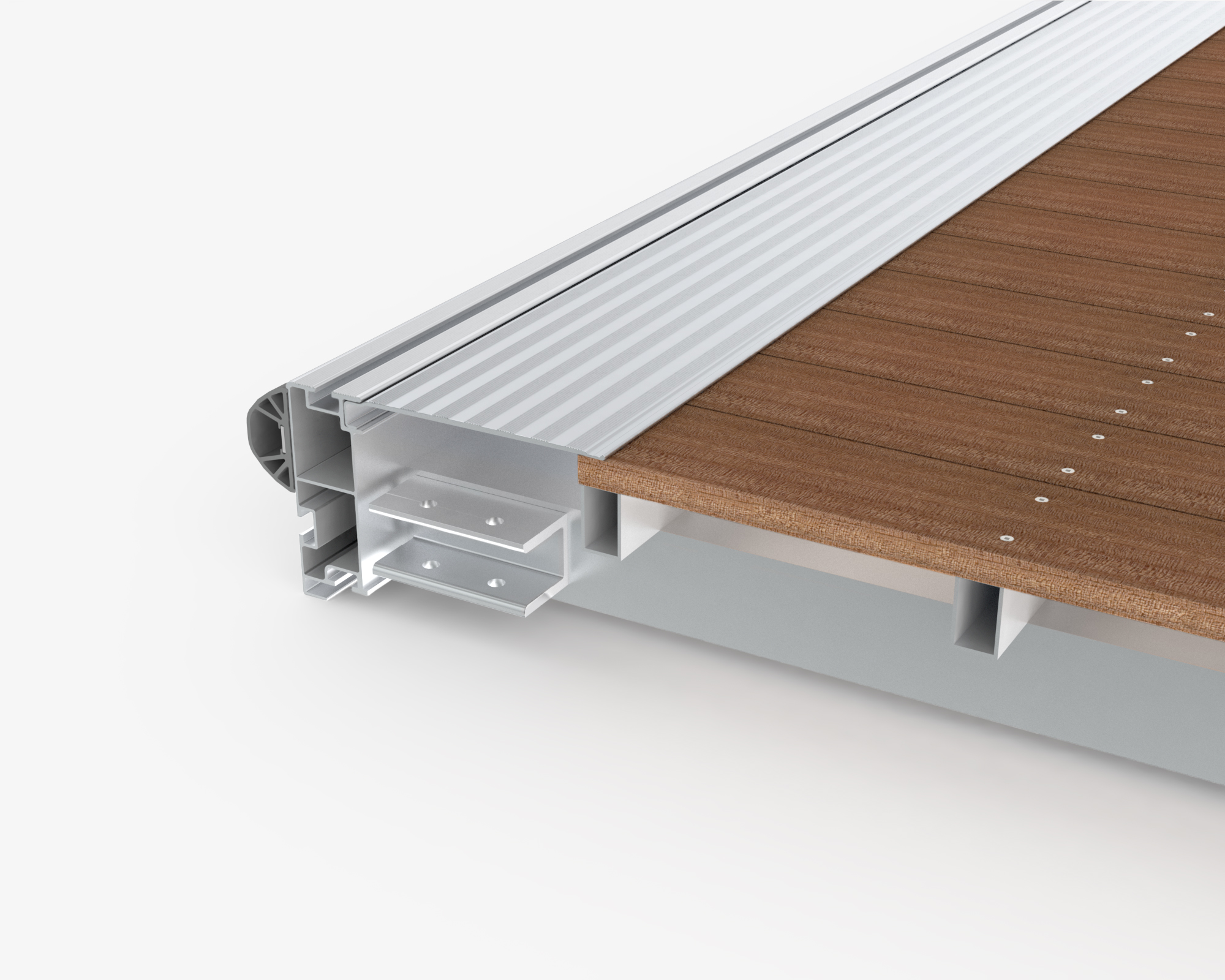

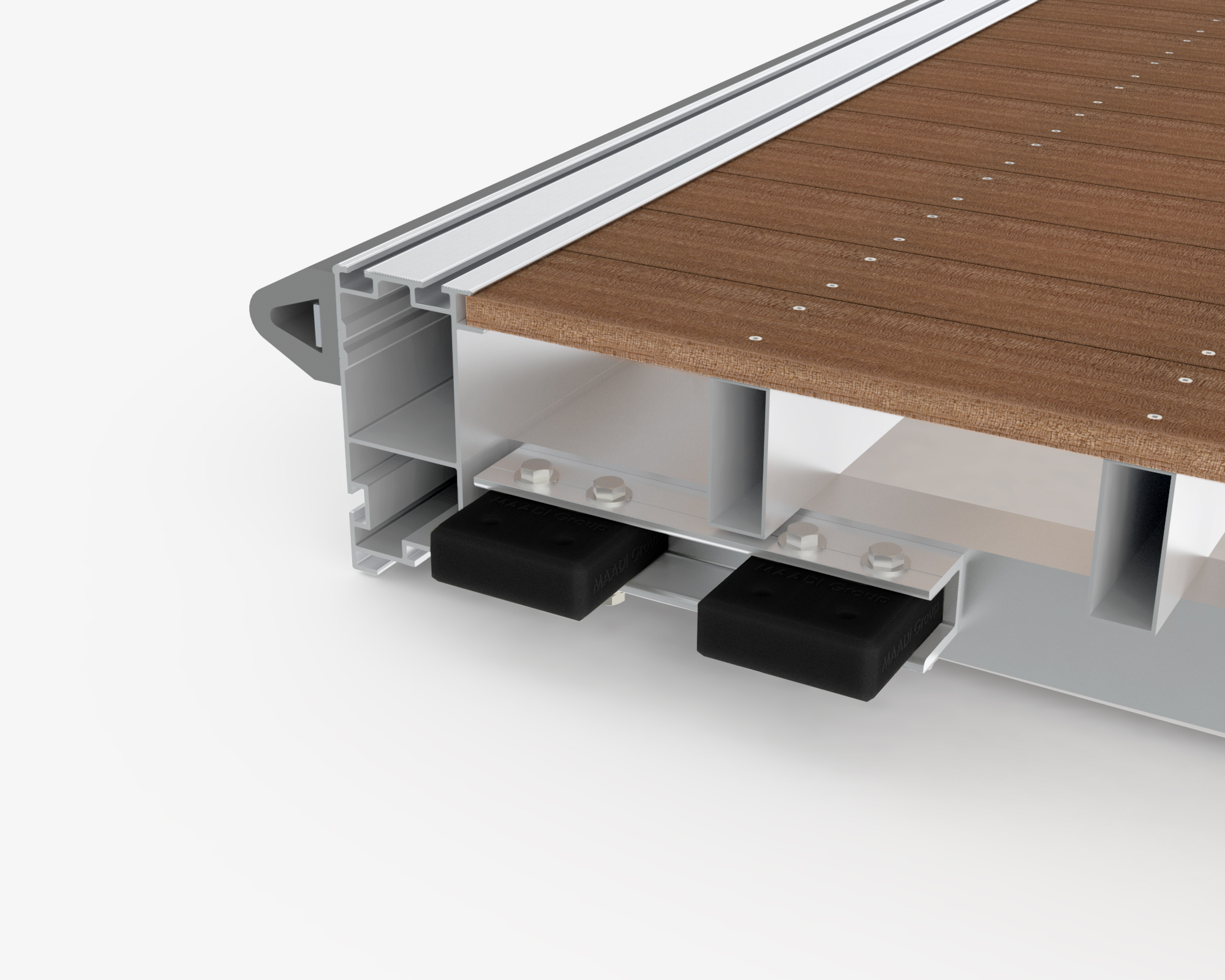

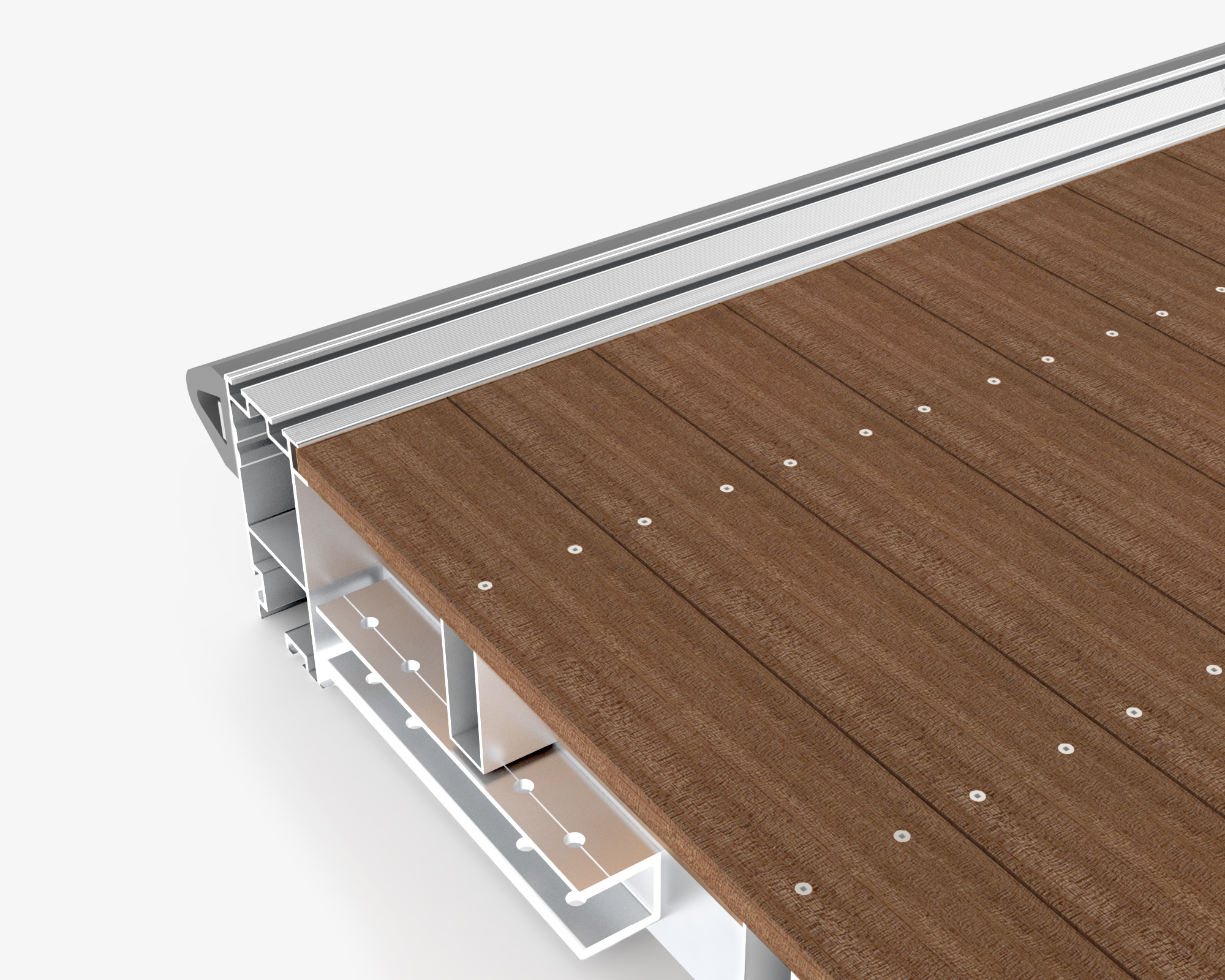

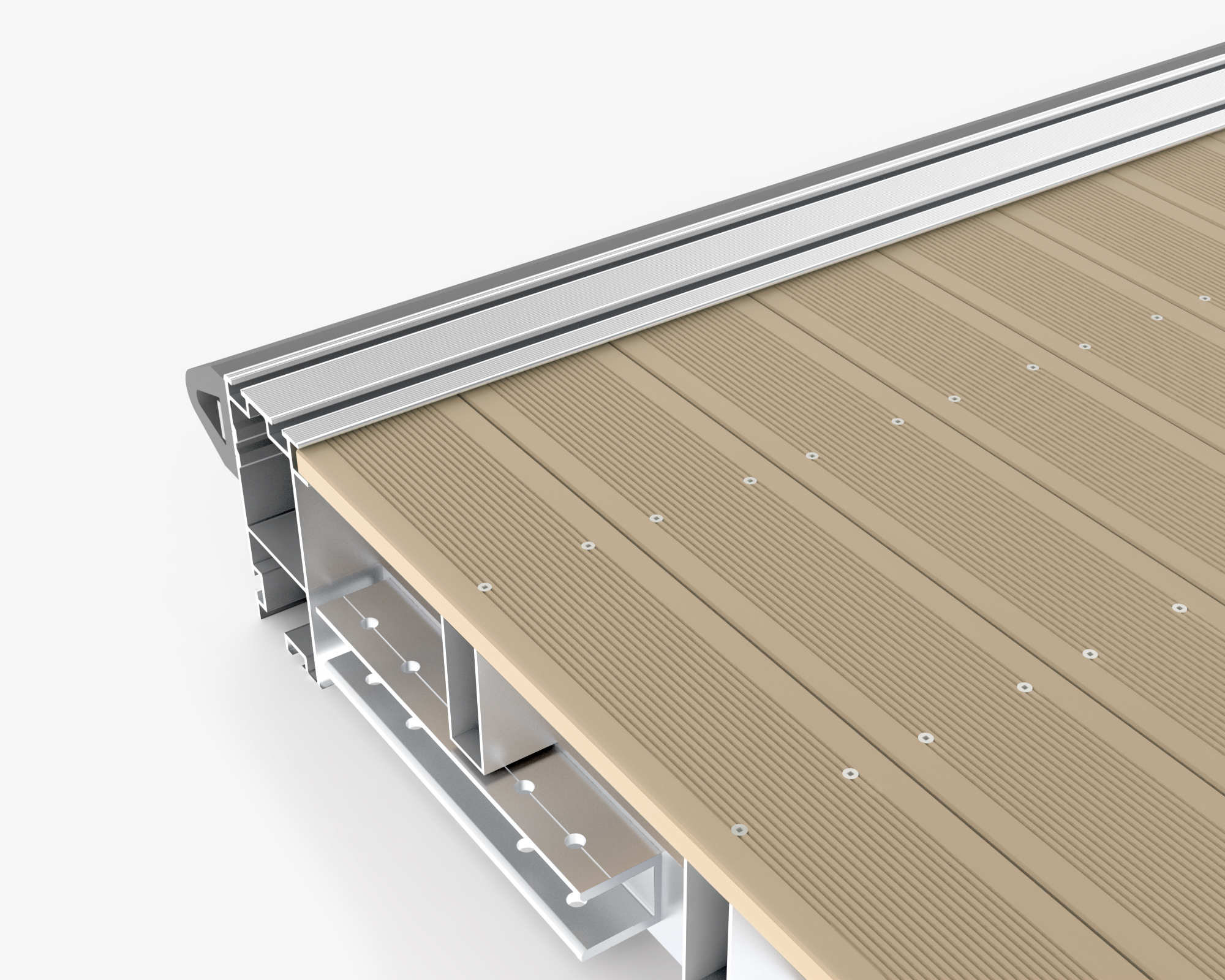

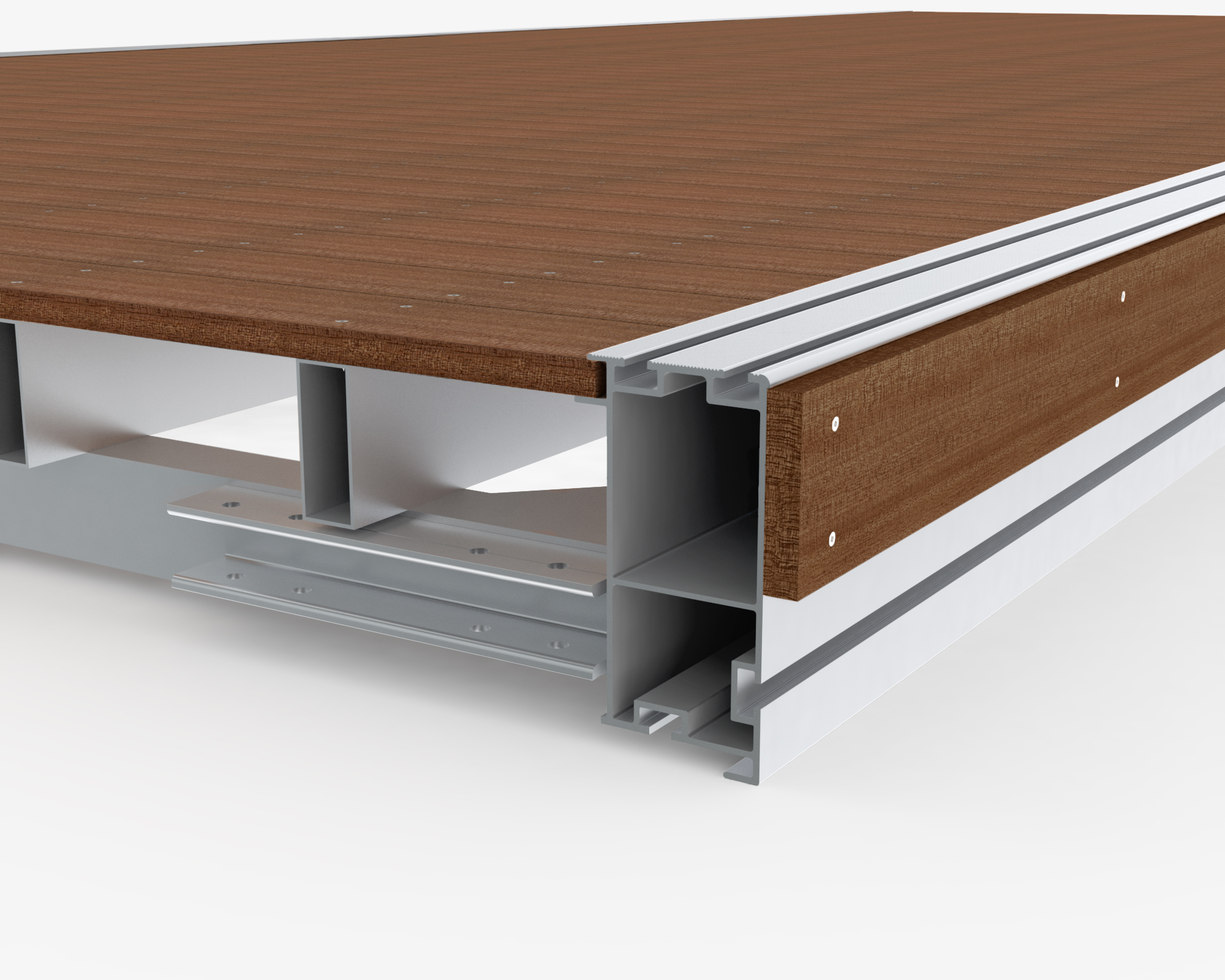

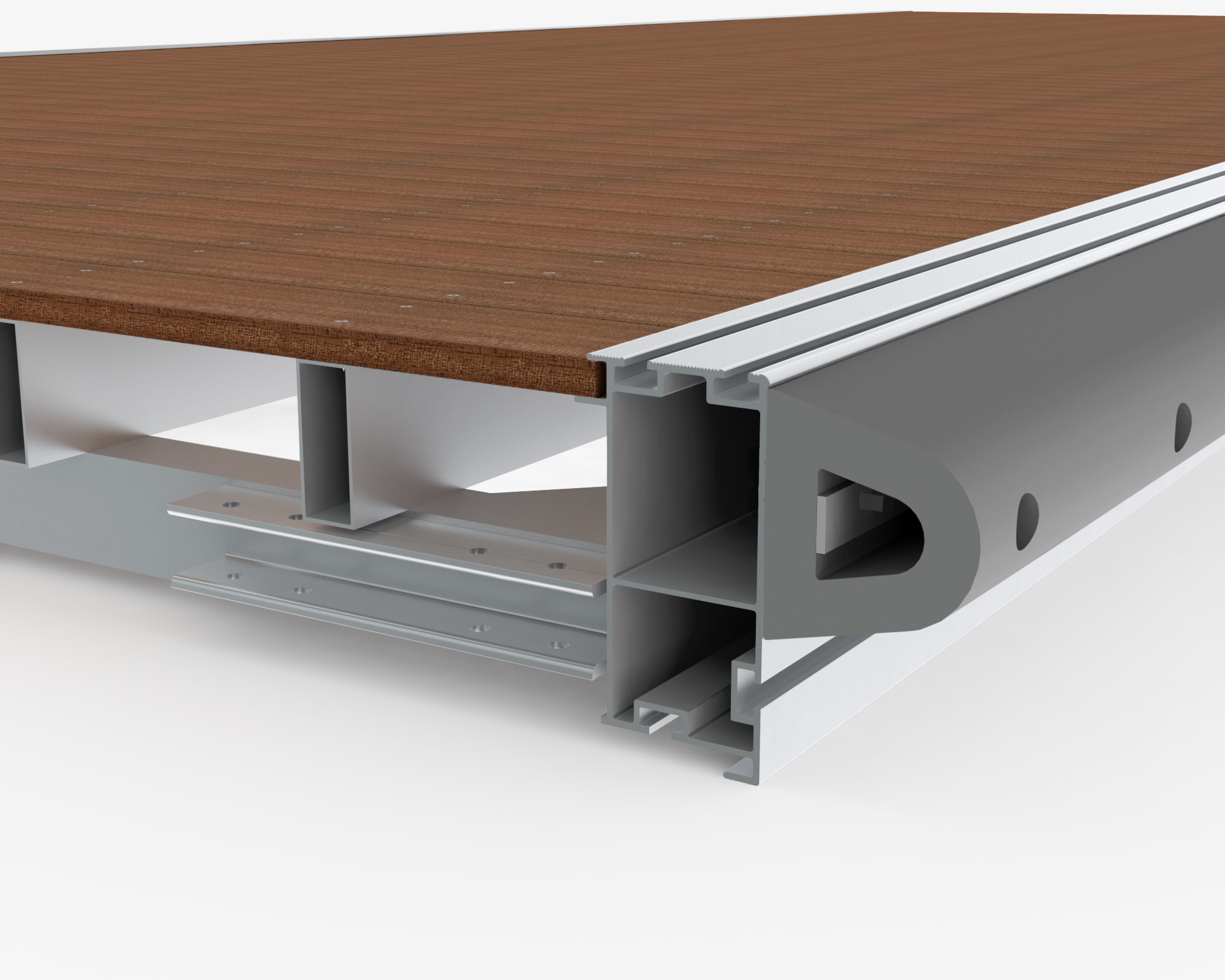

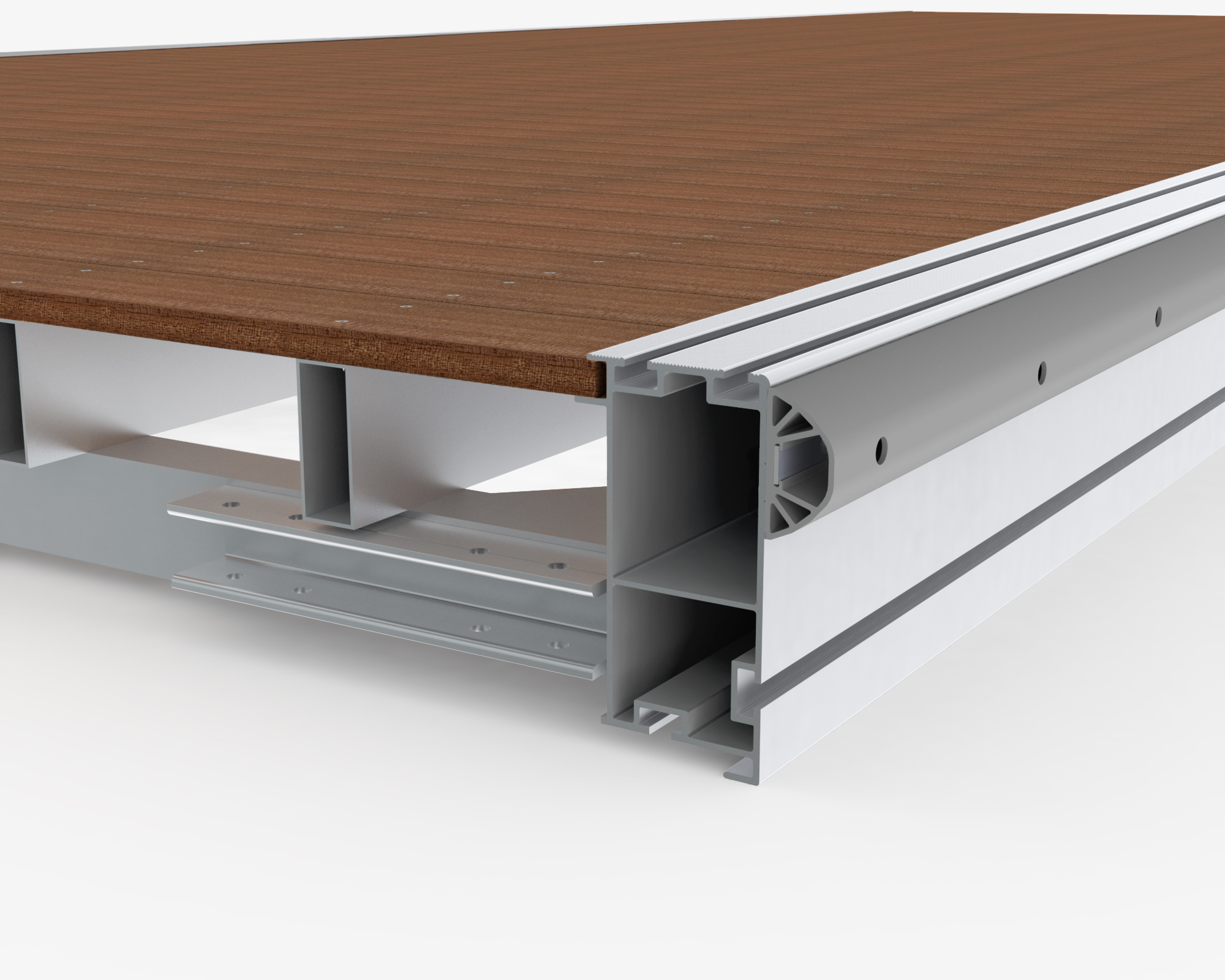

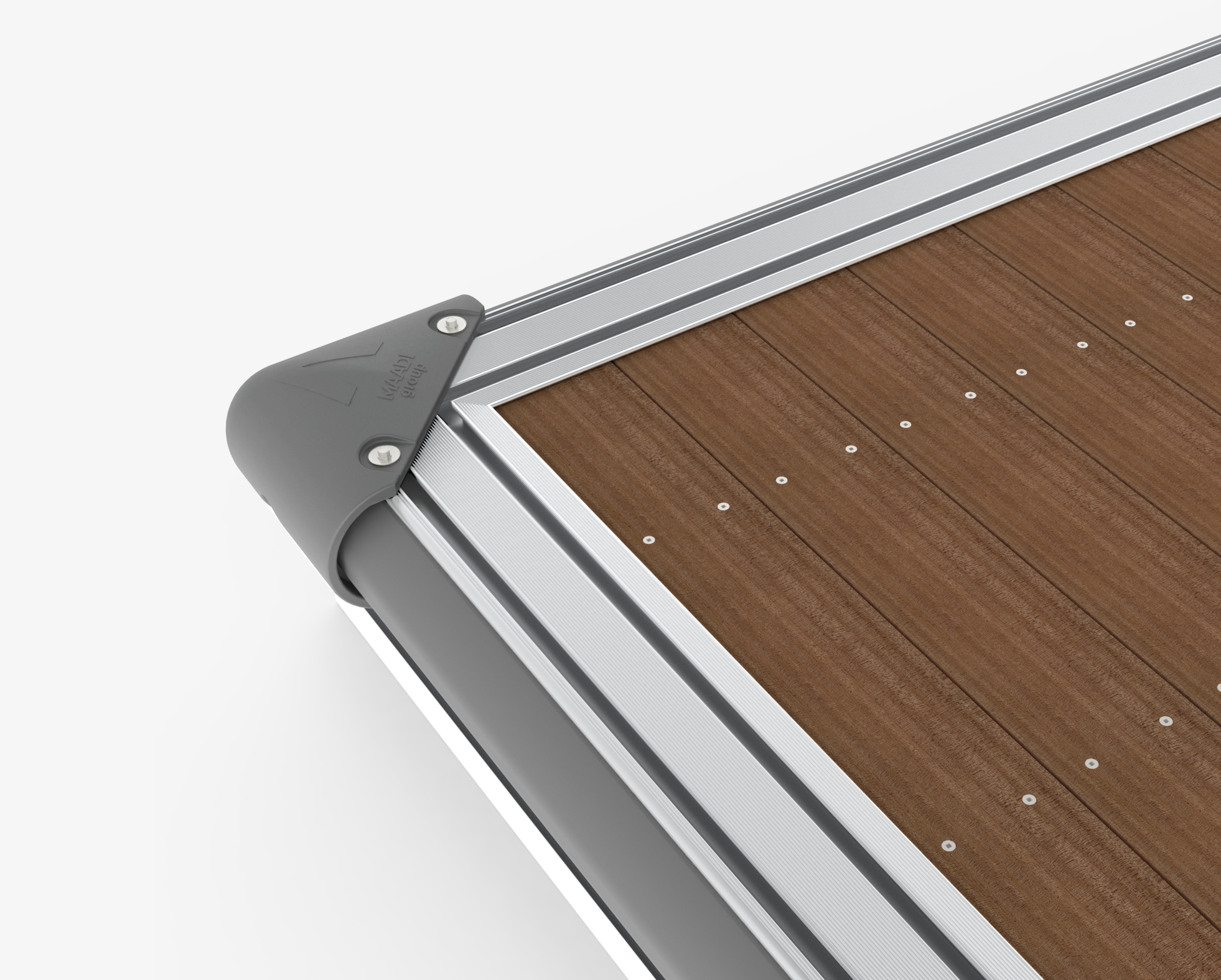

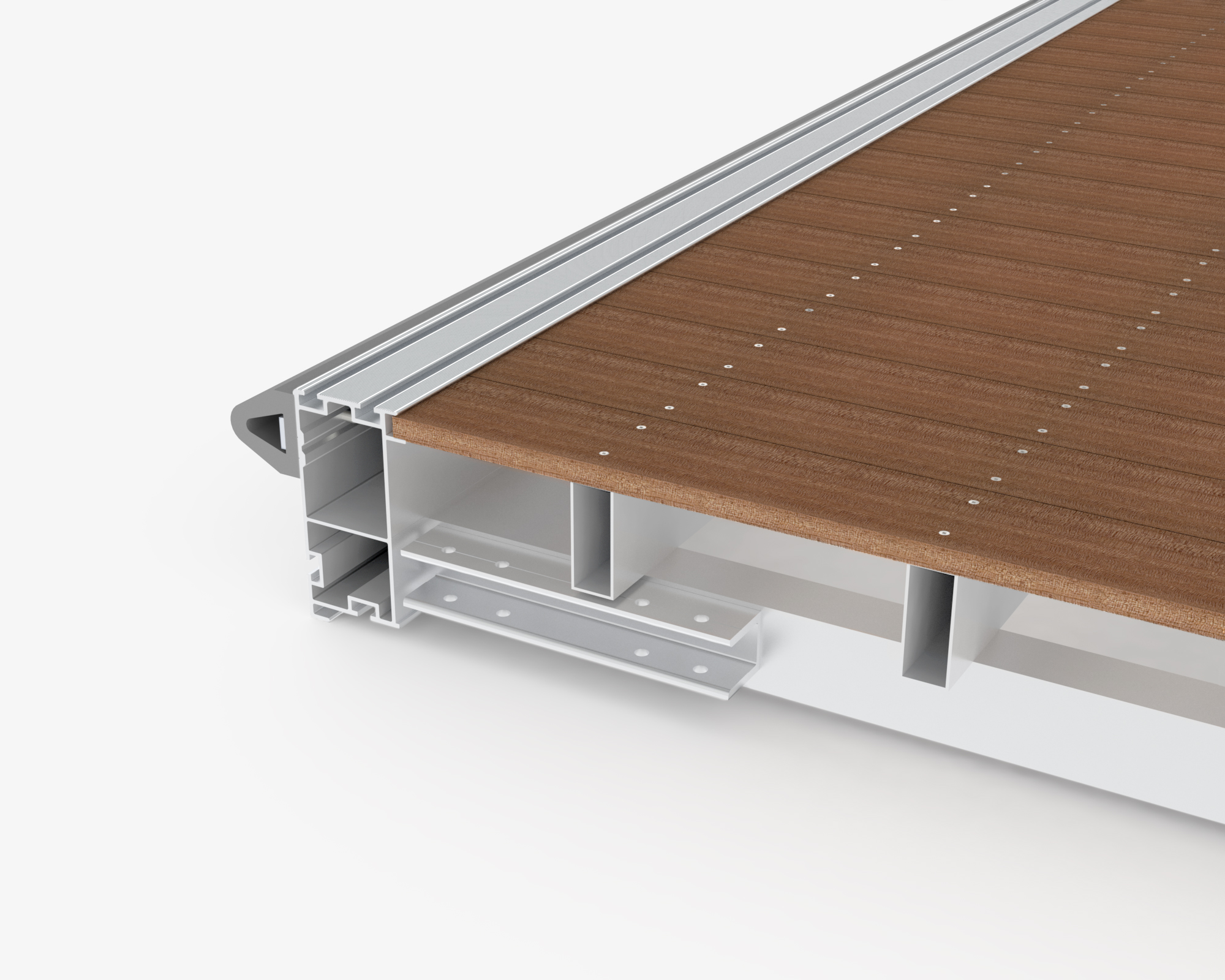

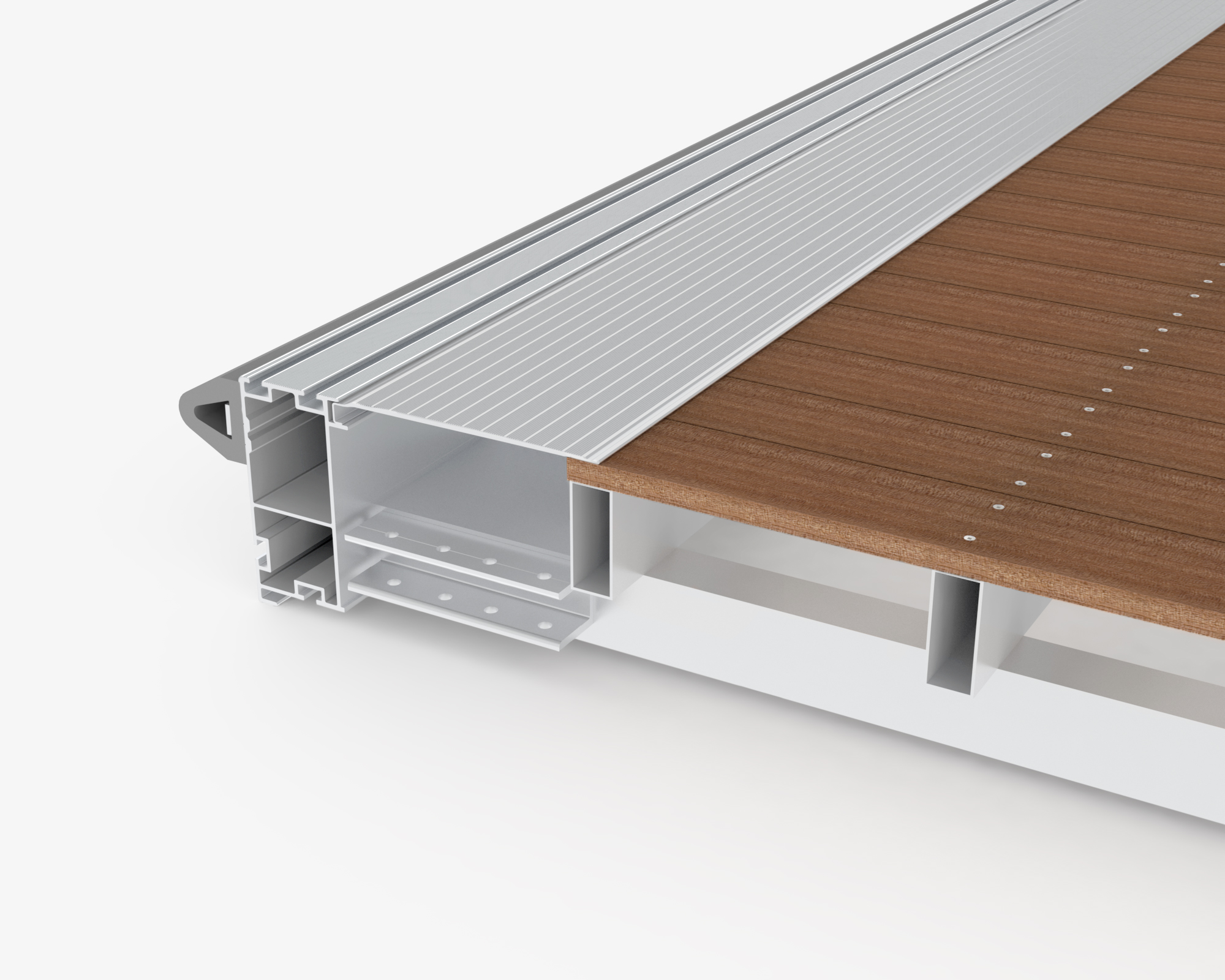

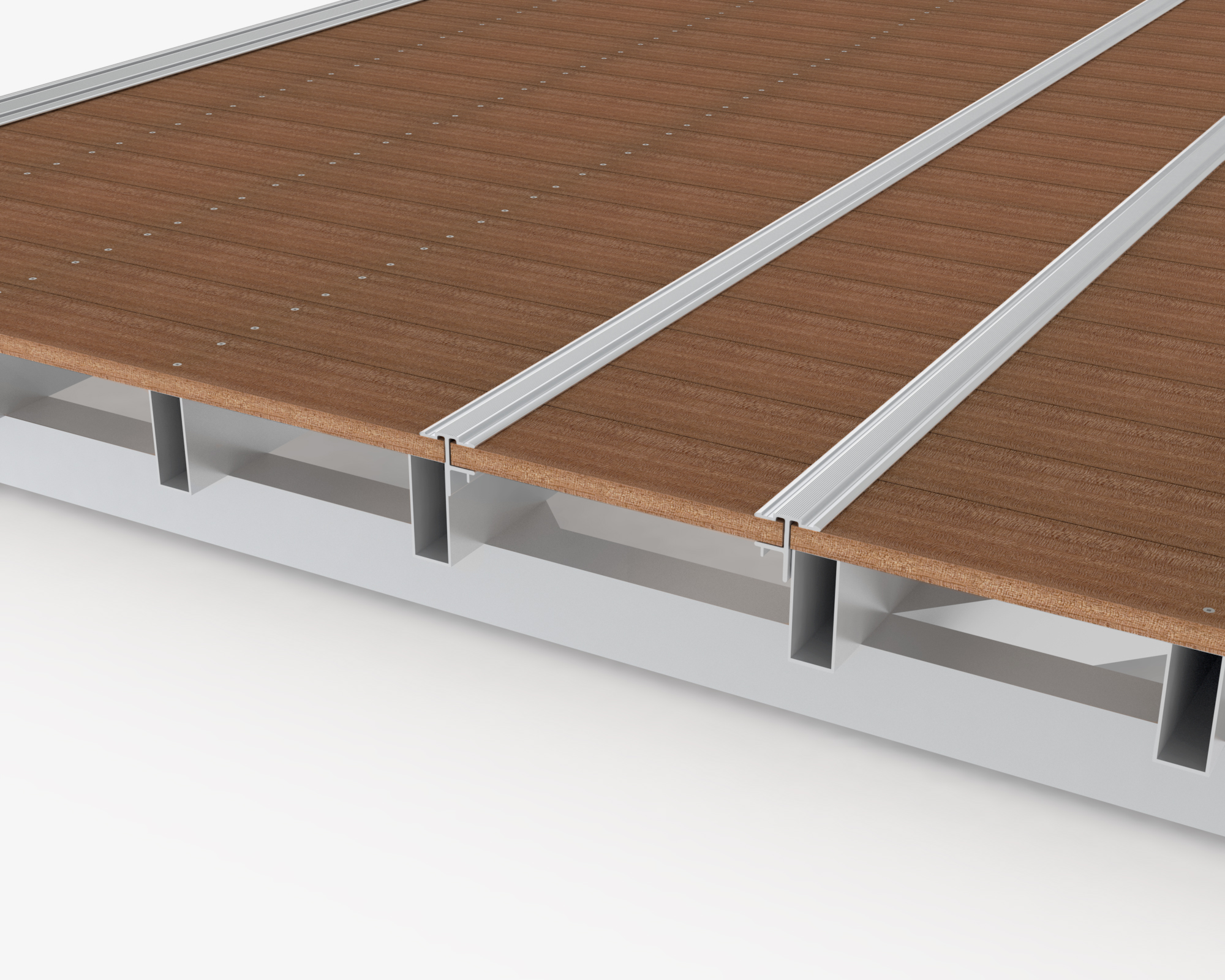

- Our aluminum floating boat docks are made with strong marine-grade extruded aluminum alloy

- They easily withstand harsh weather and the constant flow of pedestrians and golf carts

- Resistant to corrosion from salt water, chemicals, and pollution, thanks to a permanent film of natural oxide

- Unlike steel, our floating docks require far less maintenance, ensuring long-term performance

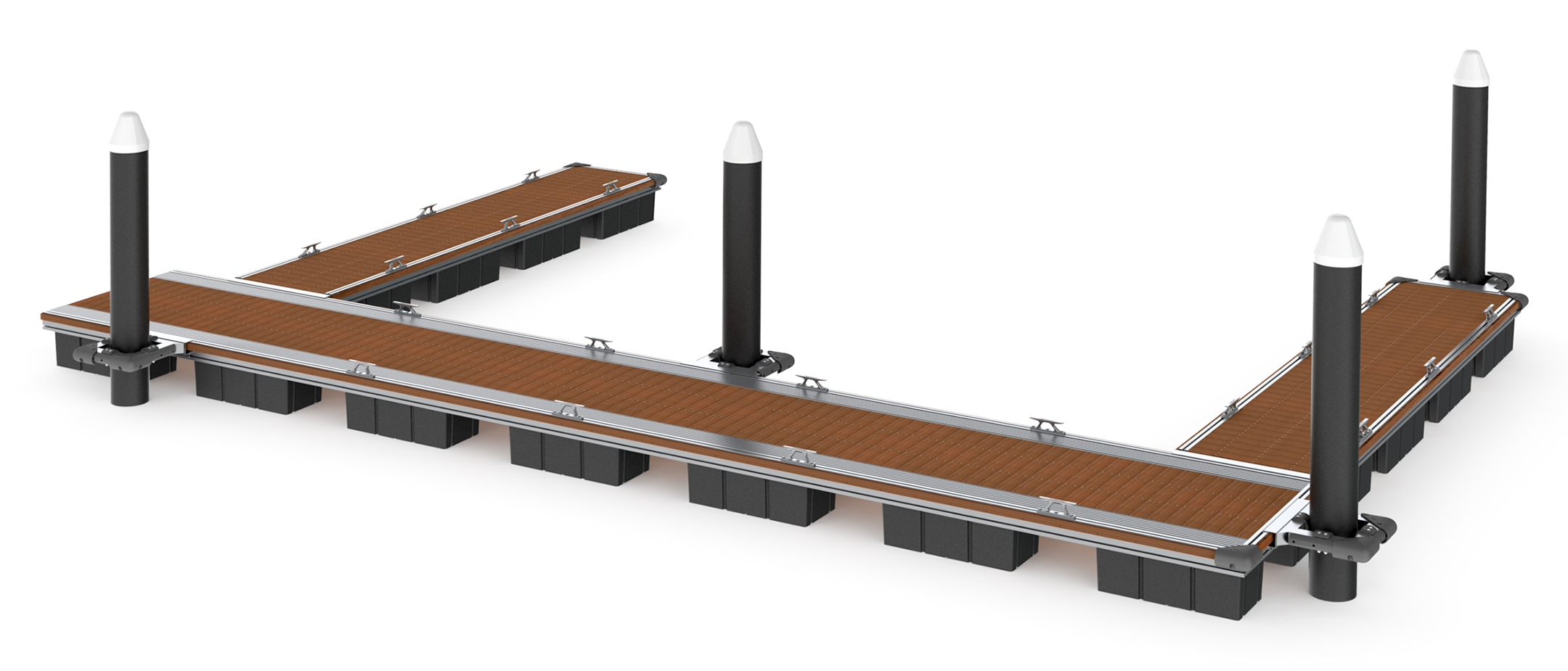

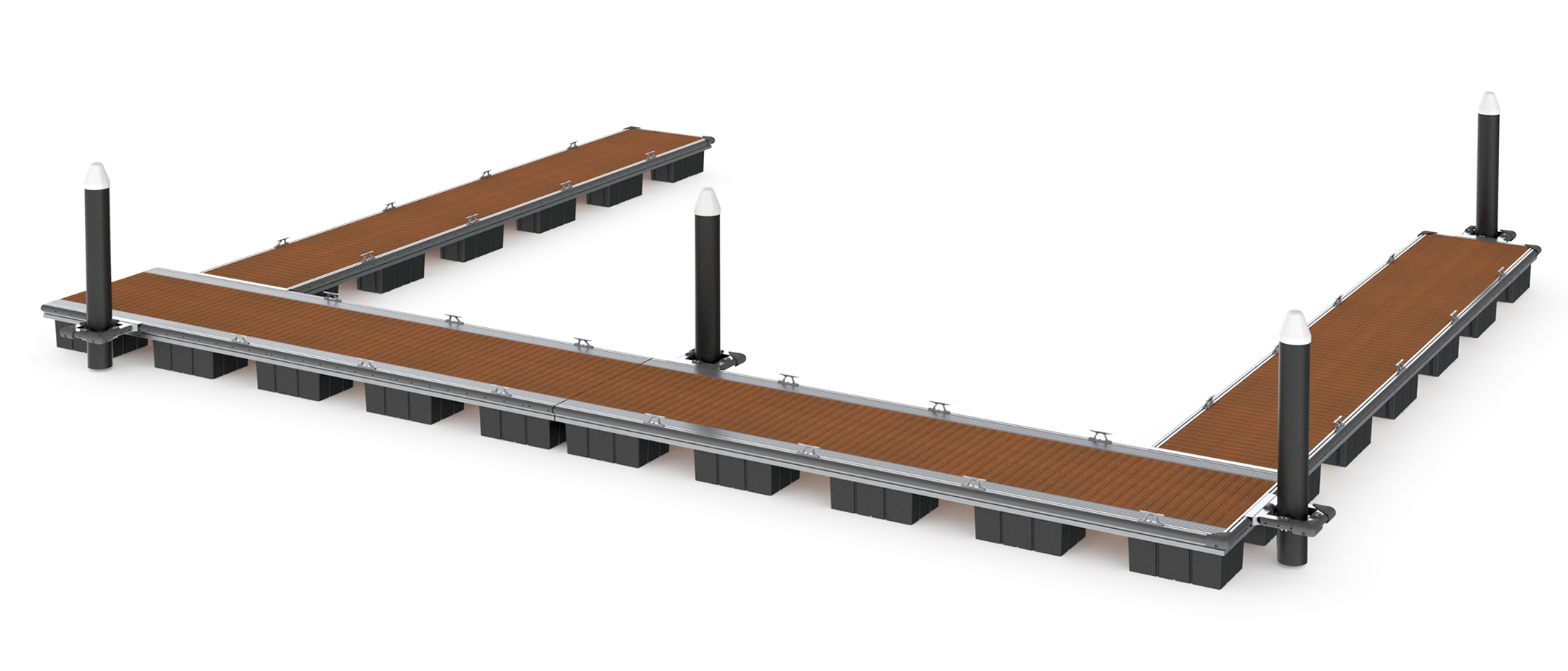

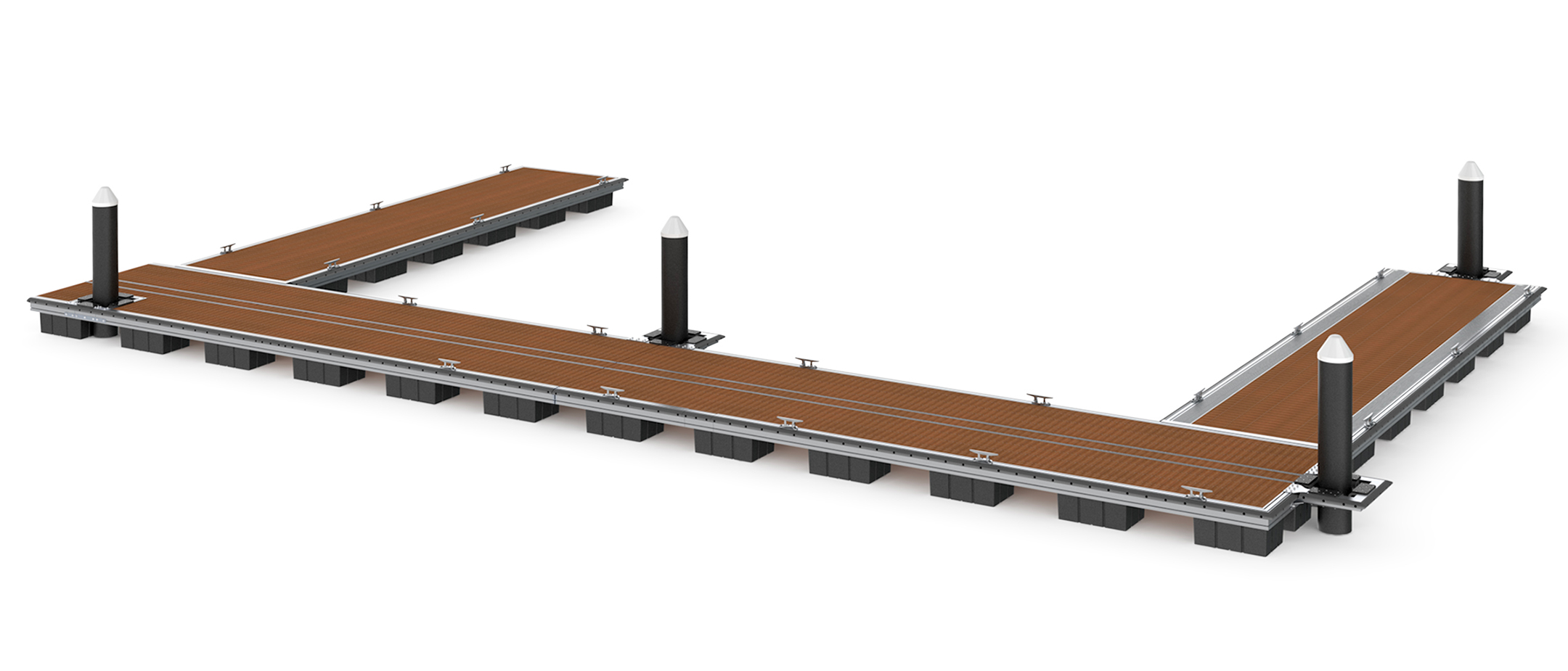

Custom design

- Our aluminum dock layouts are optimized by our experienced engineers to fit your needs

- Our custom floating docks are built to your specifications using sustainable design principles and the highest quality standards.

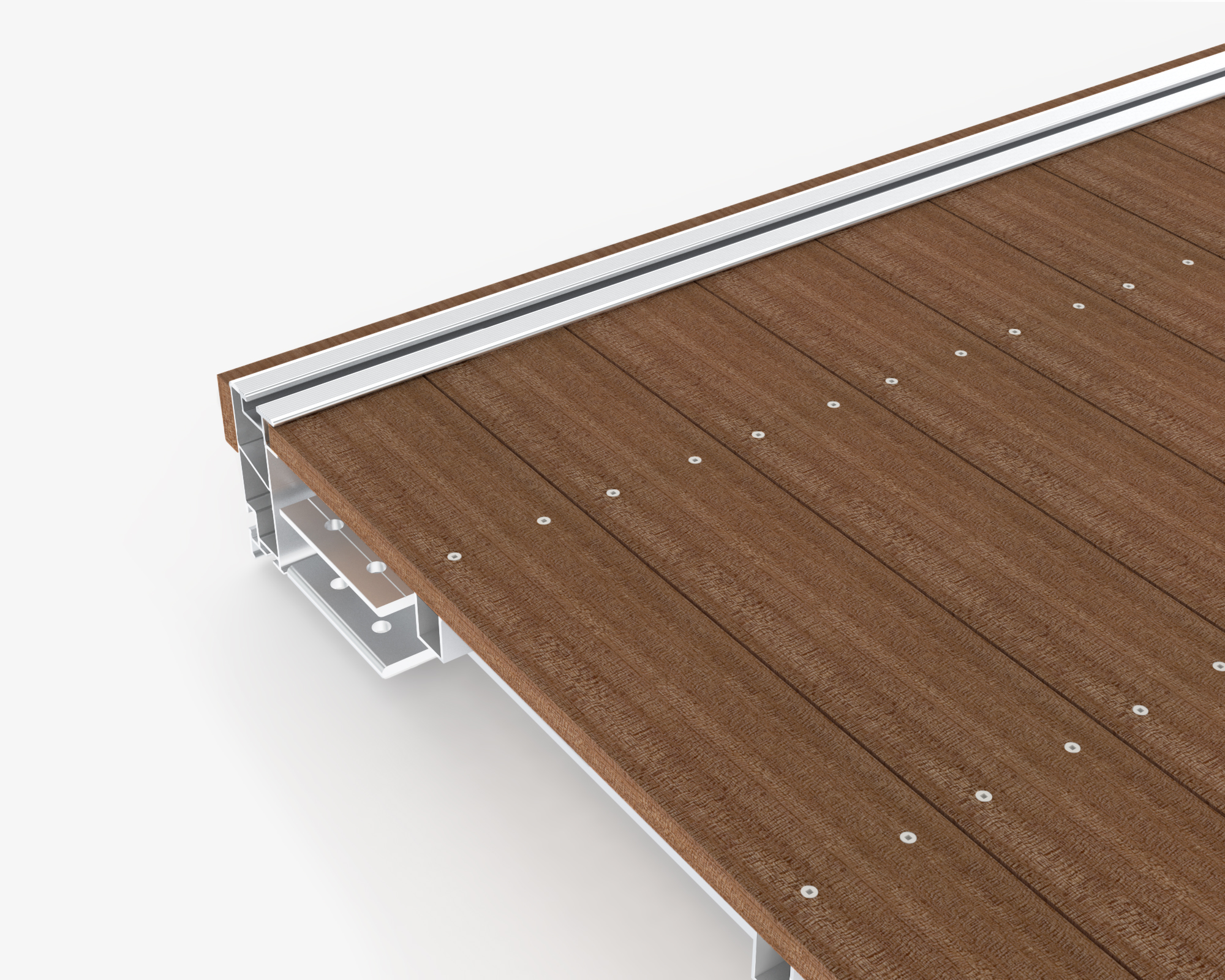

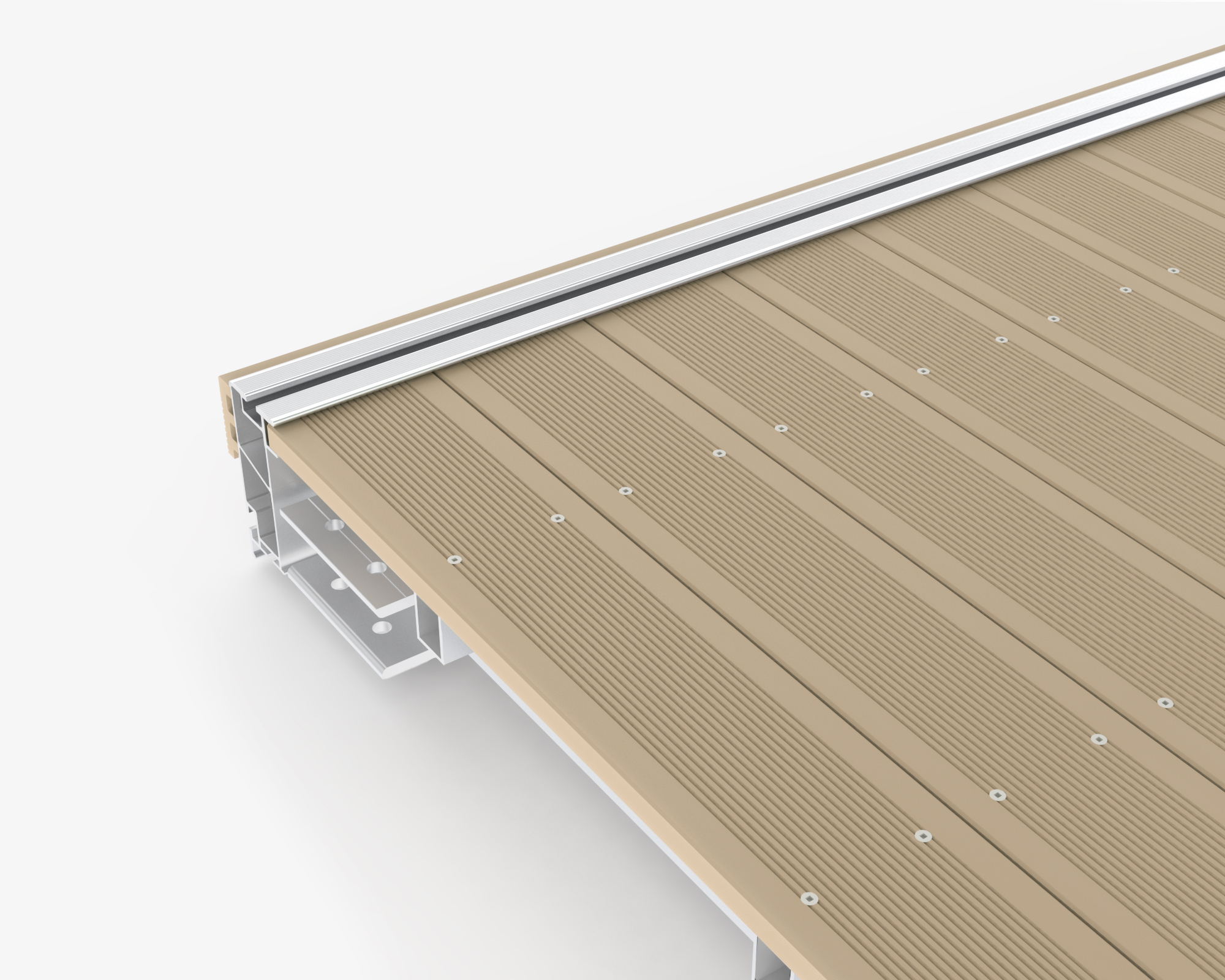

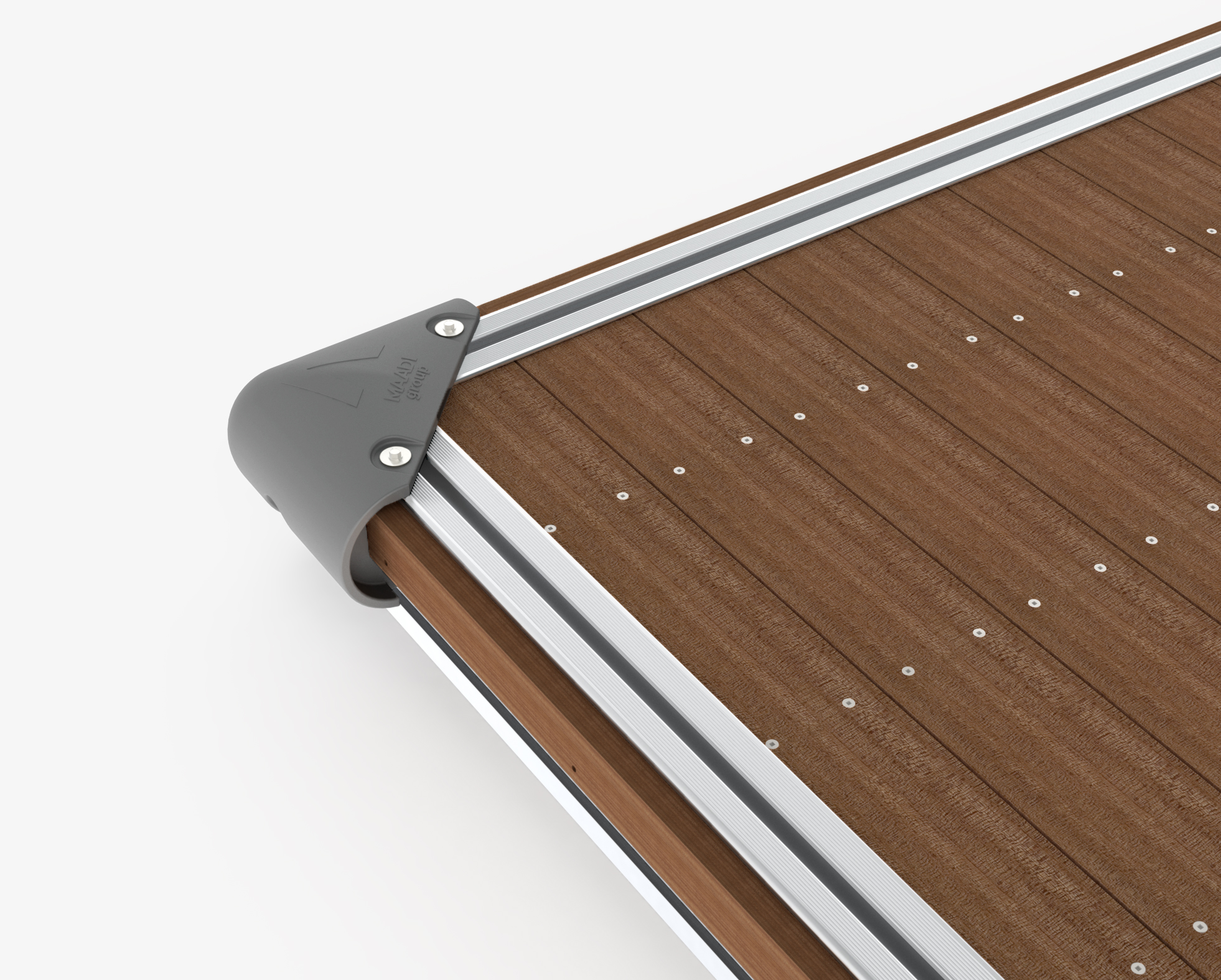

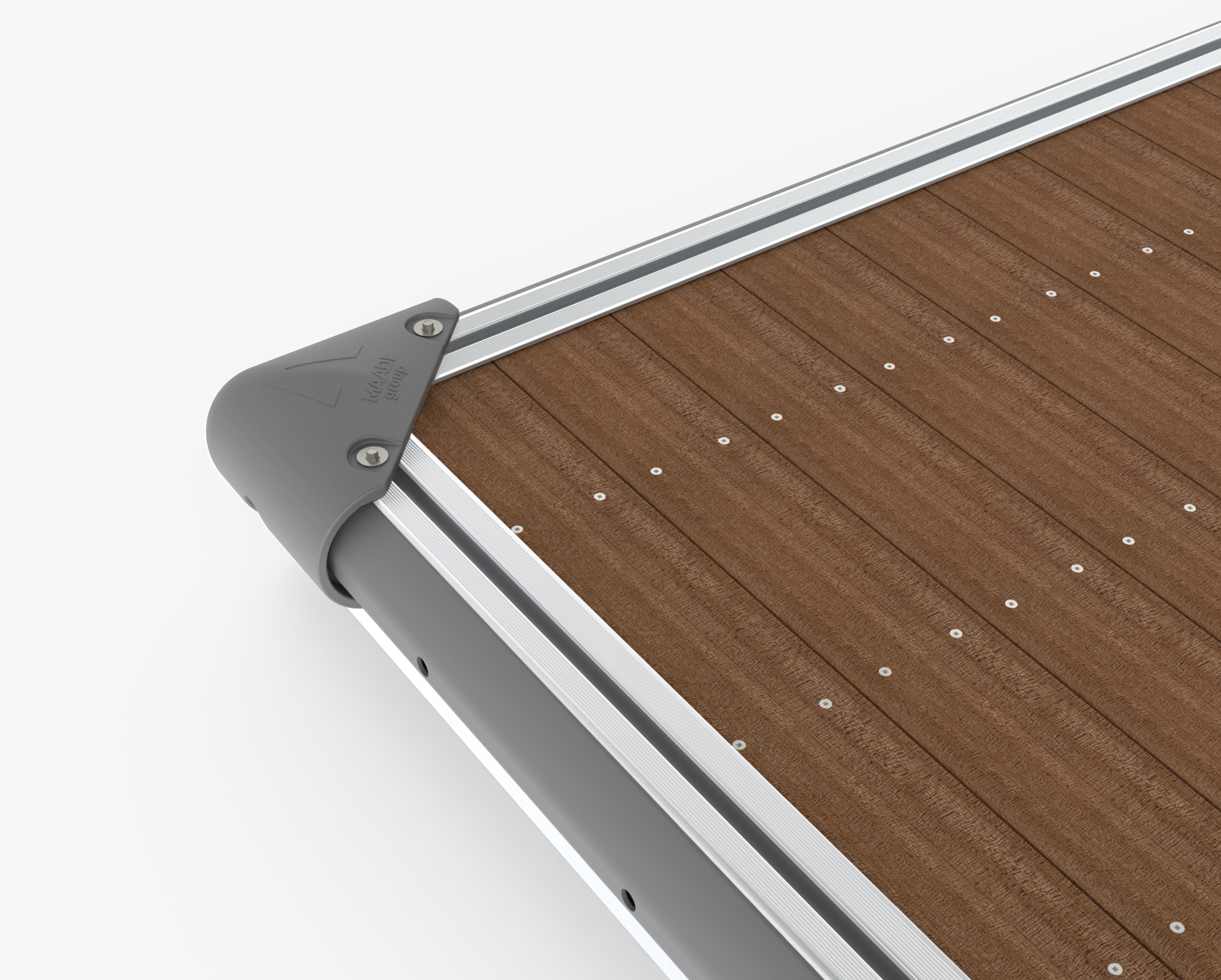

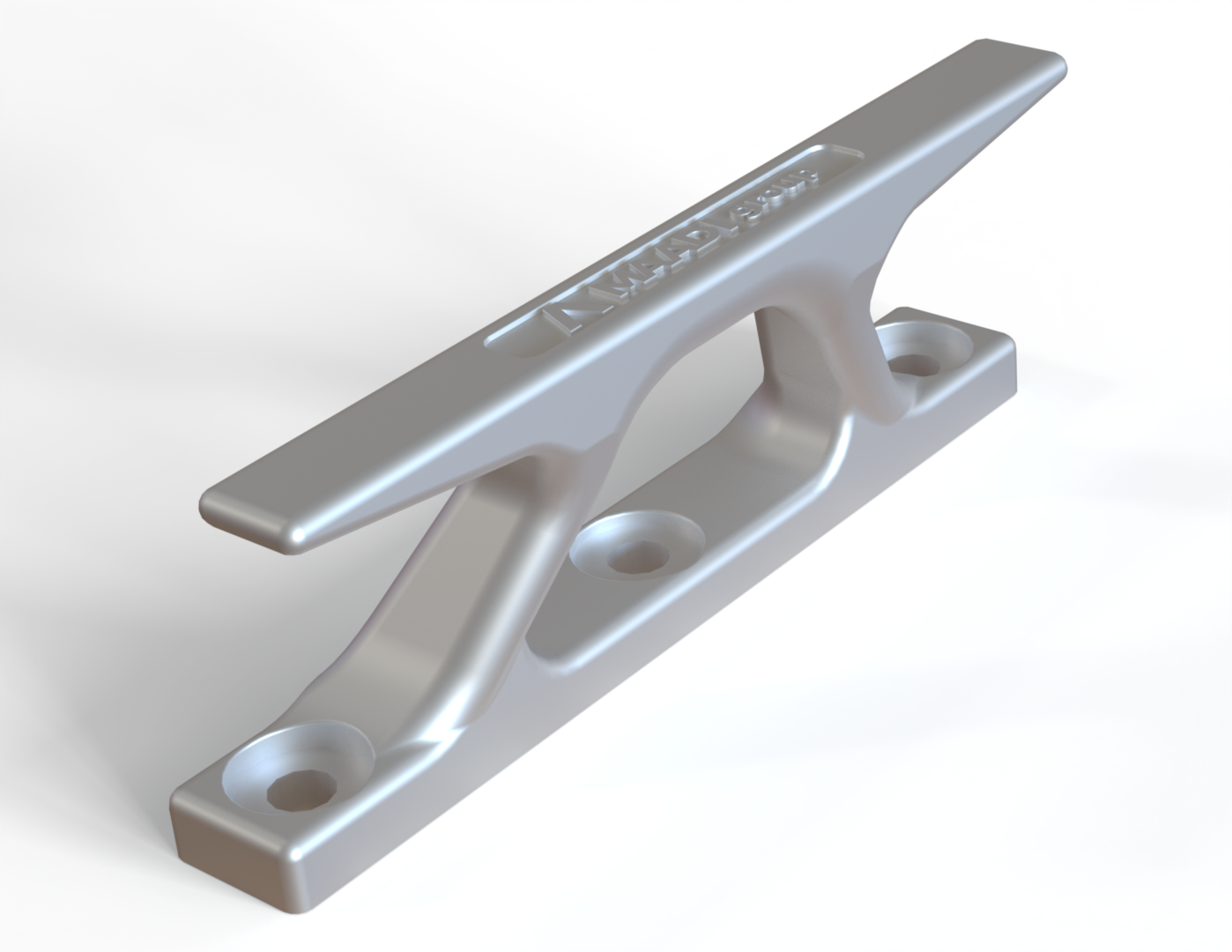

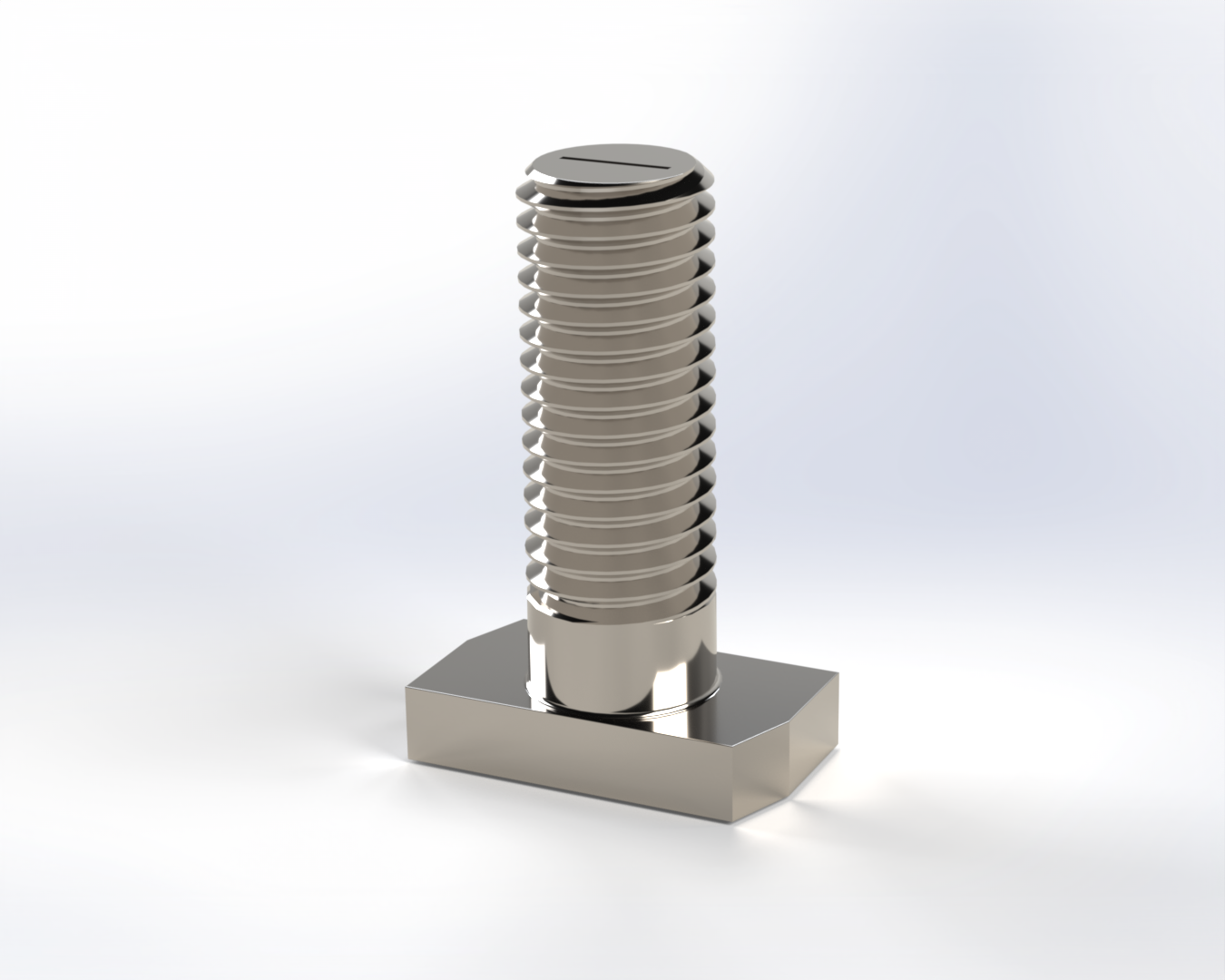

- Choose from a wide range of decking materials, utility trough covers, fenders, cleats, and accessories to personalize your system

Versatile

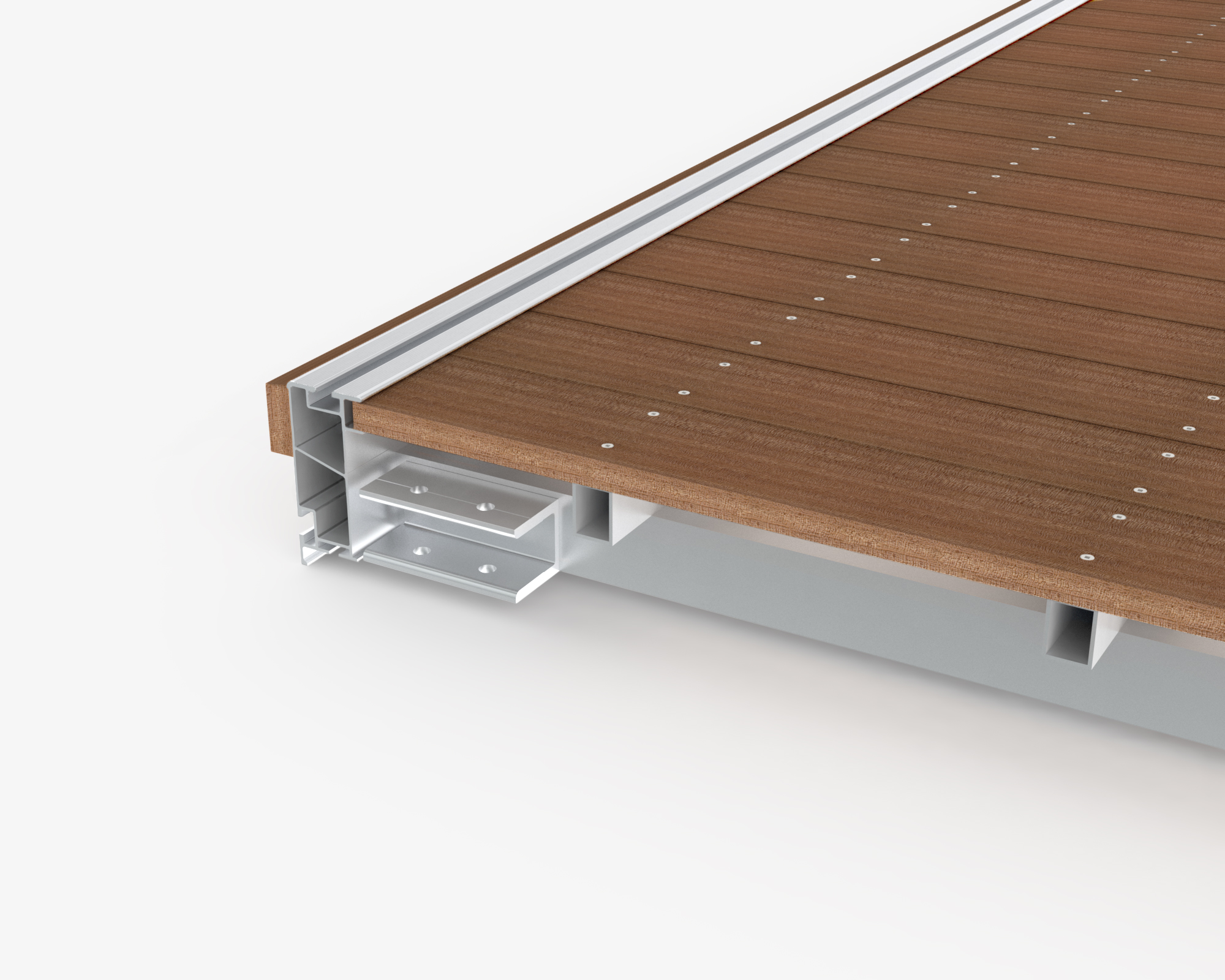

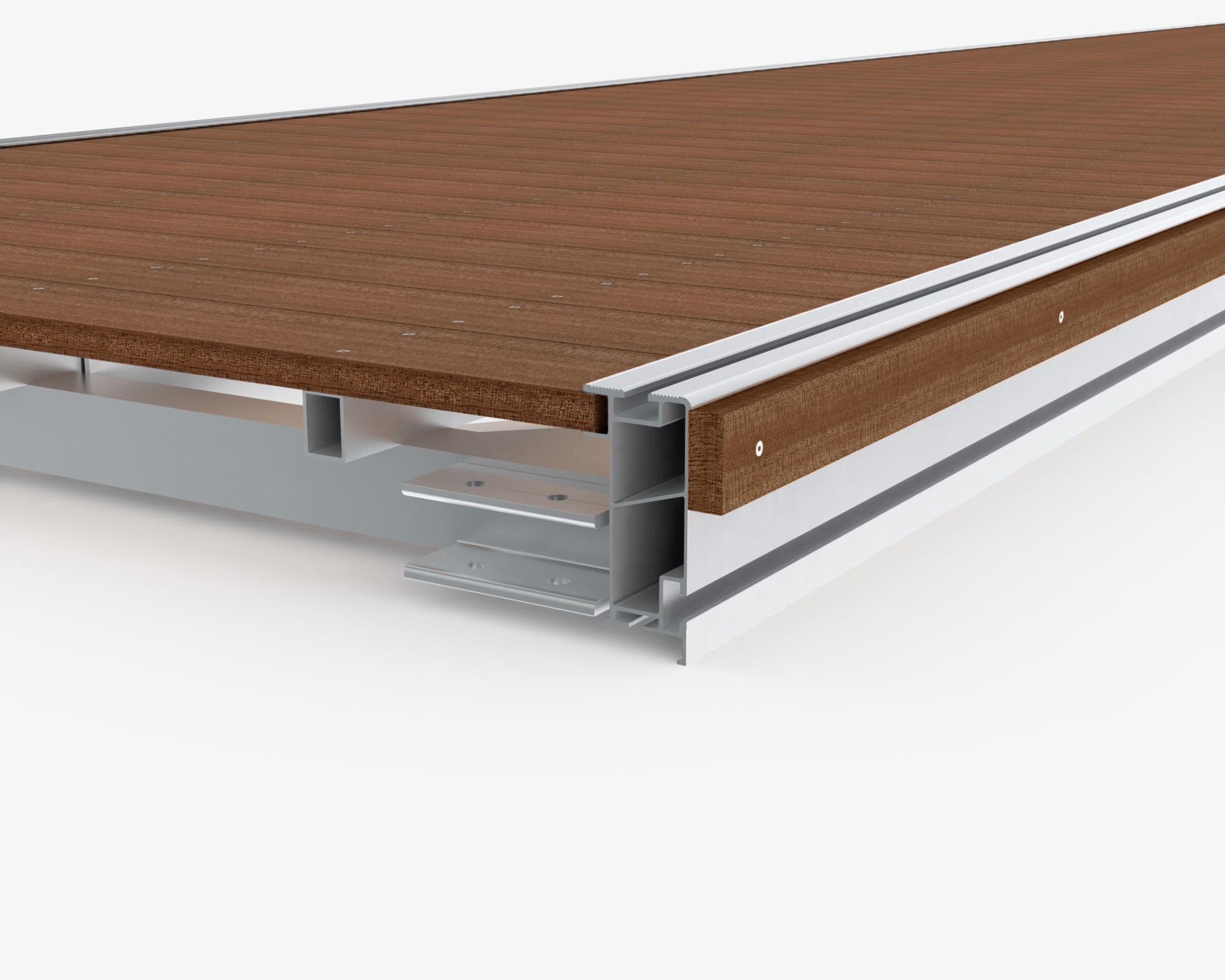

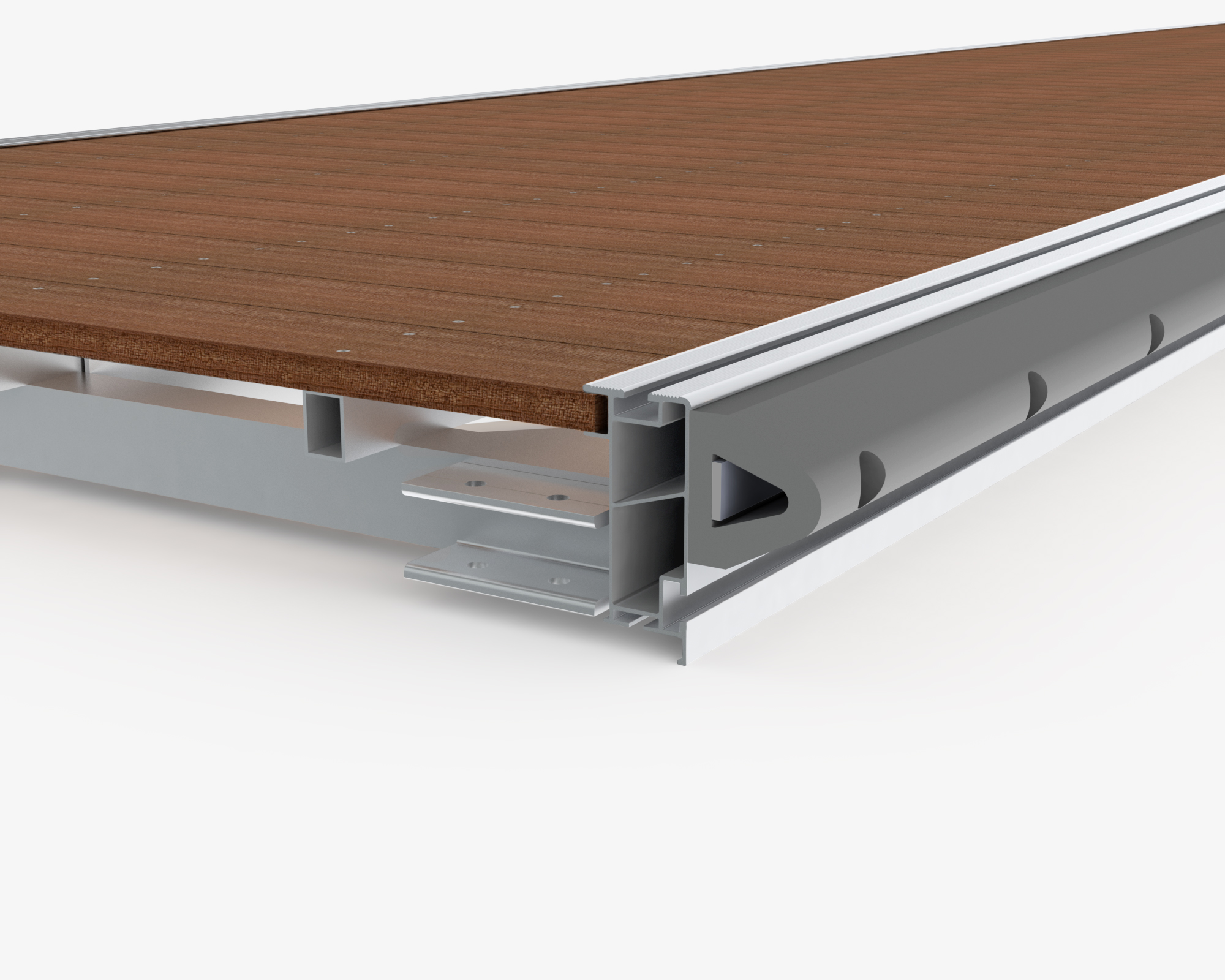

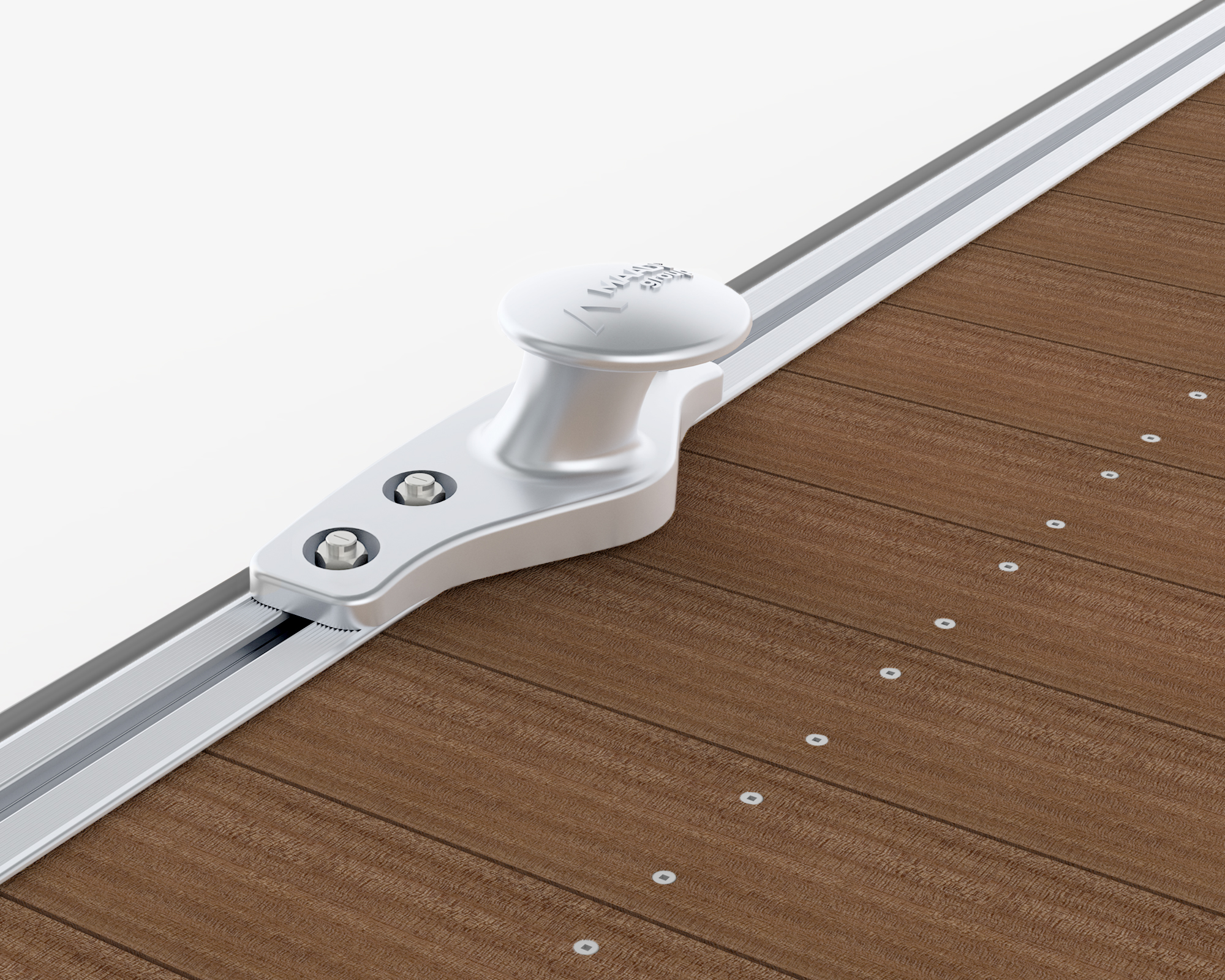

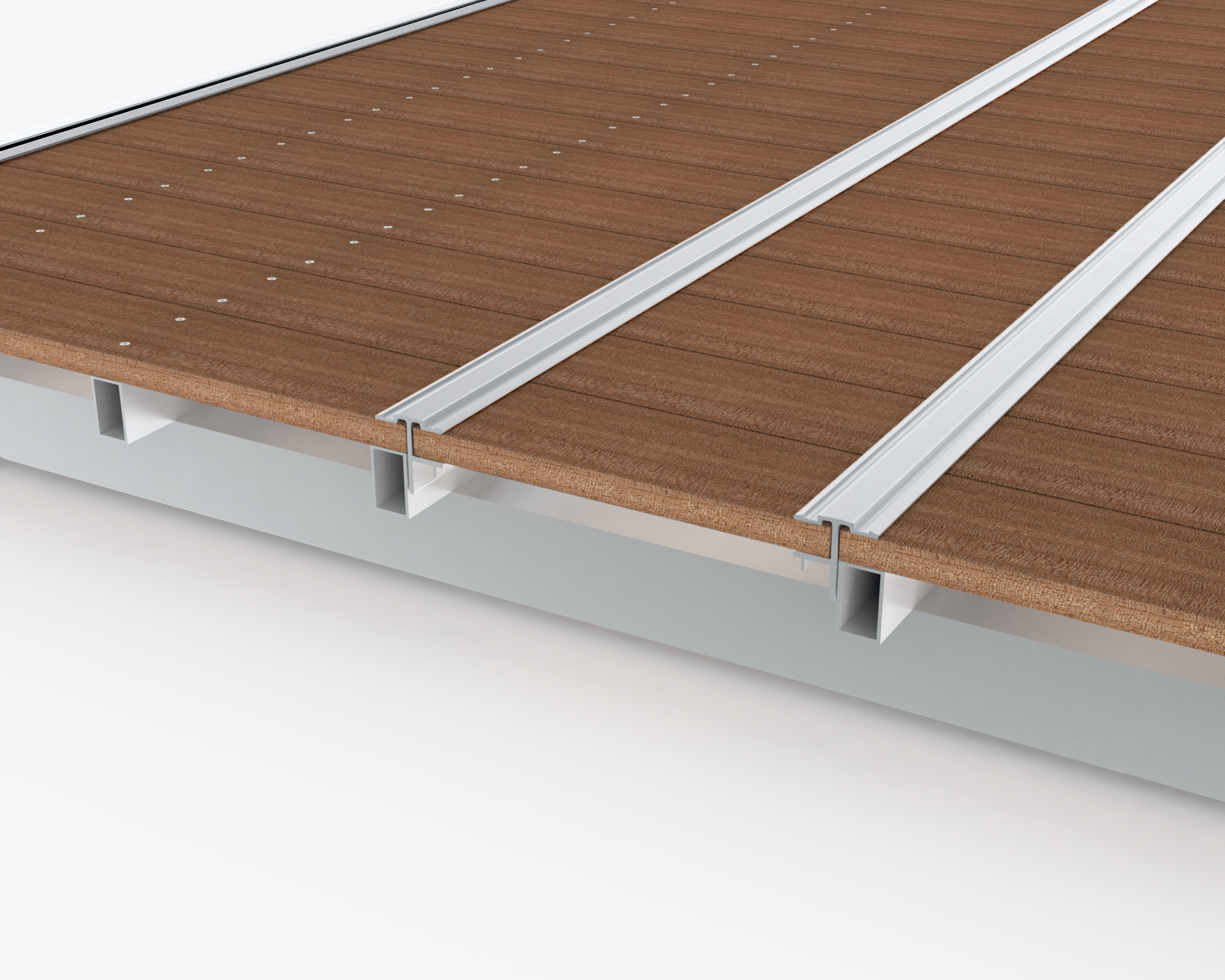

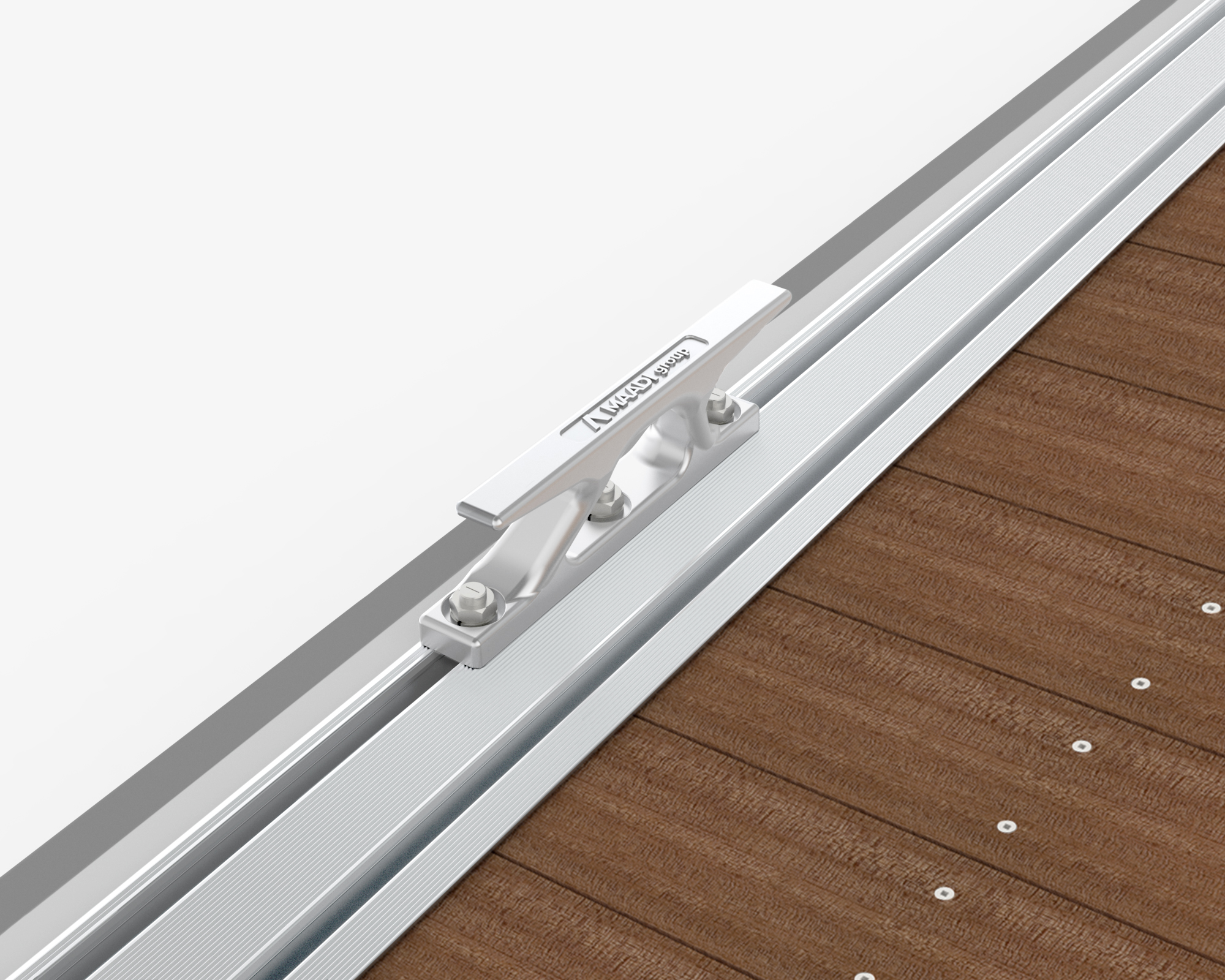

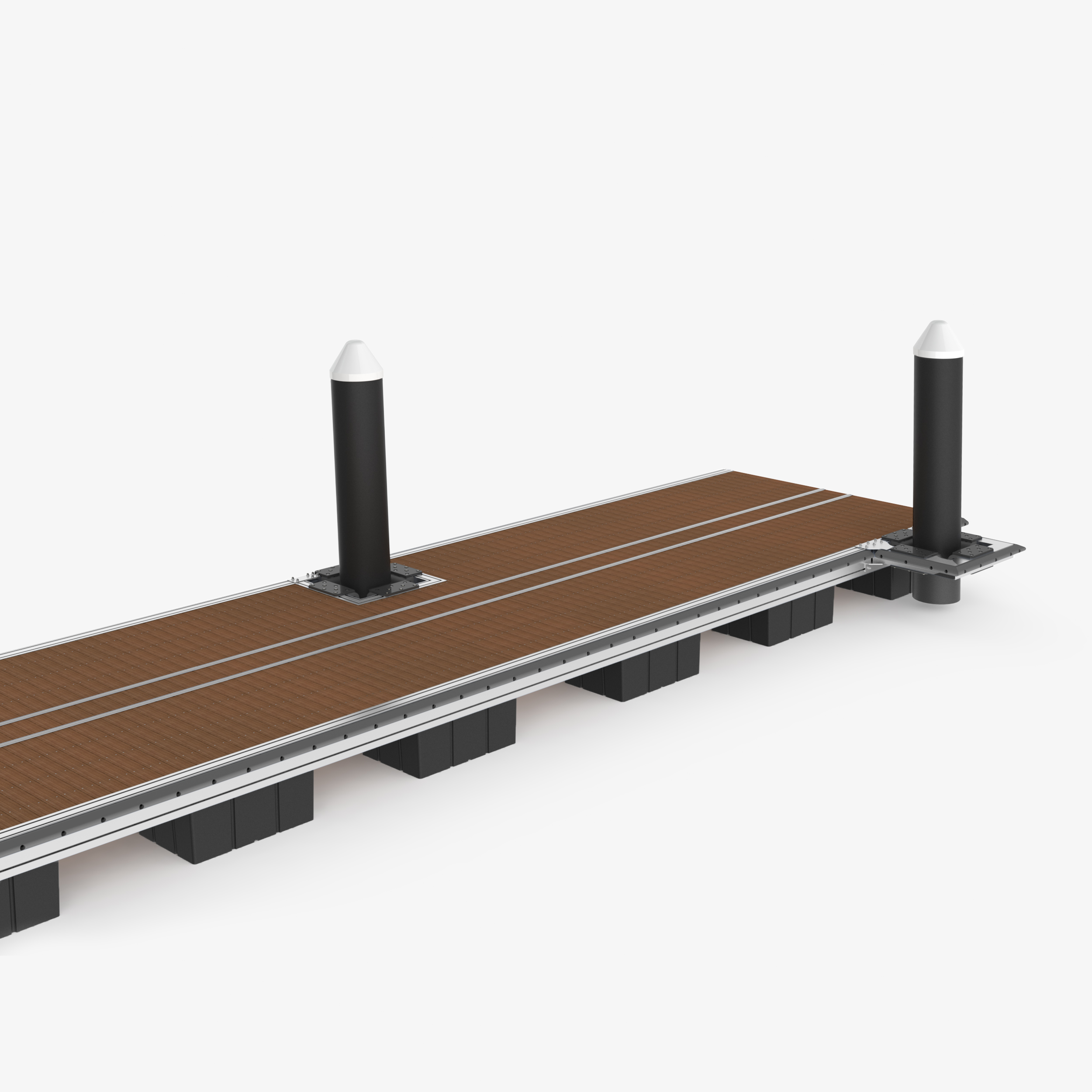

- Our aluminum floating docks and finger docks can be reconfigured easily with our multifunction track system.

- We offer three versatile systems suited for everything from small pleasure craft to luxury mega yachts.

- Whether for commercial marinas or residential floating docks, MAADI Group provides scalable, smart solutions.

Streamlined features of our floating docks

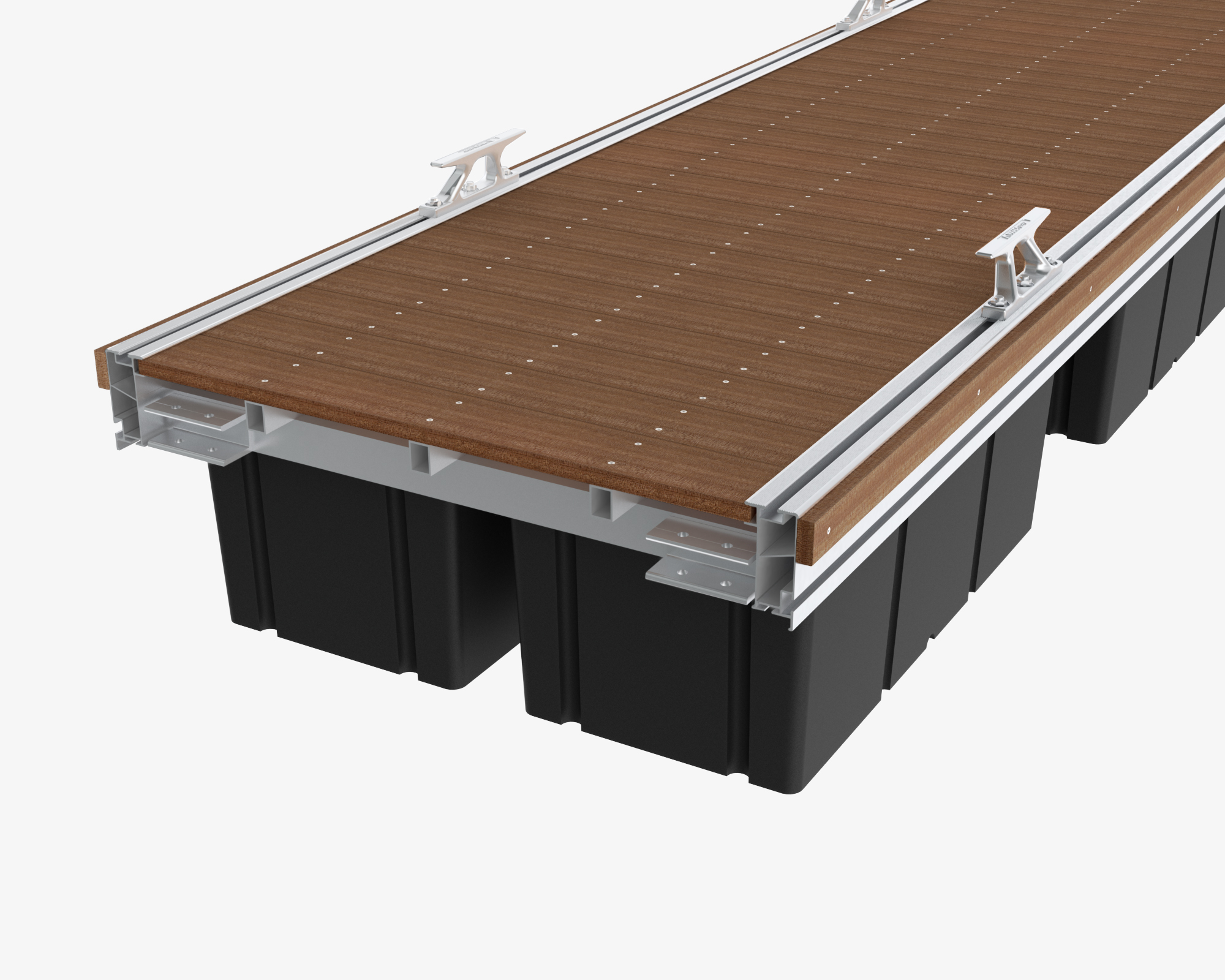

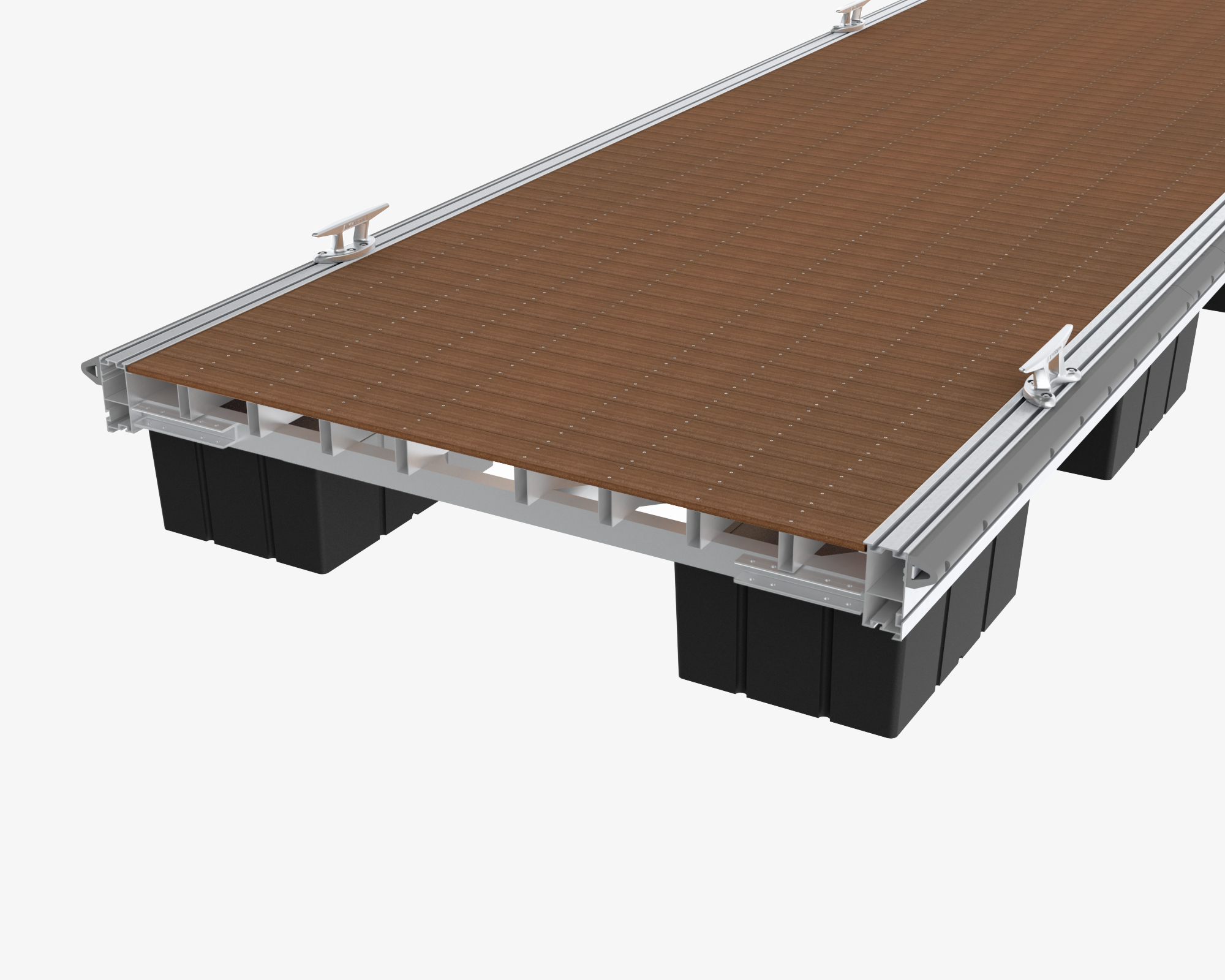

Our 3 modular floating dock systems are loaded with sleek, customizable features. And because the systems are interoperable, our engineers can combine systems to optimize your docking capacity for different size boats.

Lakeshore™

Small pleasure craft and recreational boats

Great Lakes™

Medium-sized pleasure yachts

Tri Ocean™

Large vessels and mega yachts

Compare Systems

Our modular floating dock systems are easily adaptable and configurable to recreational marinas and watercraft.

|

System characteristics |

Lakeshore™ Small pleasure craft and recreational boats |

Great Lakes™ Medium-sized pleasure yachts |

Tri Ocean™ Large vessels and mega yachts |

|---|---|---|---|

| Boat dimensions | From 20' to 40' (From 6.1 to 12.2 m) |

From 20' to 80' (From 6.1 to 24.4 m) |

From 60' to 200' (From 18.3 to 61 m) |

| Dock width | From 4' to 8' (From 1.2 m to 2.4 m) |

From 4' to 11' (From 1.2 m to 3.4 m) |

From 4' to 16' (From 1.2 m to 4.9 m) |

| Dock length | Up to 42' (12.8 m) | Up to 42' (12.8 m) | Up to 42' (12.8 m) |

| Standard freeboard | From 10" to 20" (From 254 to 508 mm) |

From 14" to 24" (From 356 to 610 mm) |

From 16" to 36" (From 406 to 914 mm) |

| Reserve buoyancy | From 20 to 30 psf (From 0.96 to 1.44 kPa) |

From 30 to 50 psf (From 1.44 to 2.39 kPa) |

From 35 to 80 psf (From 1.68 to 3.83 kPa) |

| Vertical load-bearing capacity | Up to 100 psf (4.8 kPa) |

Up to 150 psf (7.2 kPa) |

Up to 200 psf (9.6 kPa) |

| Horizontal load-bearing capacity | 246 psf – 150 lb/ft (12 kN/m2 – 223 kg/m) |

246 psf – 150 lb/ft (12 kN/m2 – 223 kg/m) |

1,337 psf – 1,250 lb/ft (64 kN/m2 – 1,860 kg/m) |

| Impact resistance | 22-ton boat, 1.6 fps (0.5 m/s) at 10º angle absorbed over 3' (900 mm) of dock length |

60-ton boat, 1.6 fps (0.5 m/s) at 10º angle absorbed over 3' (900 mm) of dock length |

240-ton boat, 1.6 fps (0.5 m/s) at 10º angle absorbed over 3' (900 mm) of dock length |

| Stability | Maximum tilt angle: 10º with live load on one side of dock | ||

| Weather conditions | Severe storms Winds of 74 mph (120 km/h) |

Category 2 hurricane with winds of 110 mph (175 km/h) | |

| Cleats | 12" – up to 3,200 lb (305 mm – up to 14 kN) |

12" – up to 3,200 lb (305 mm – up to 14 kN) |

12" – up to 3,200 lb (305 mm – up to 14 kN) 20" – up to 11,400 lb (508 mm – up to 51 kN) |

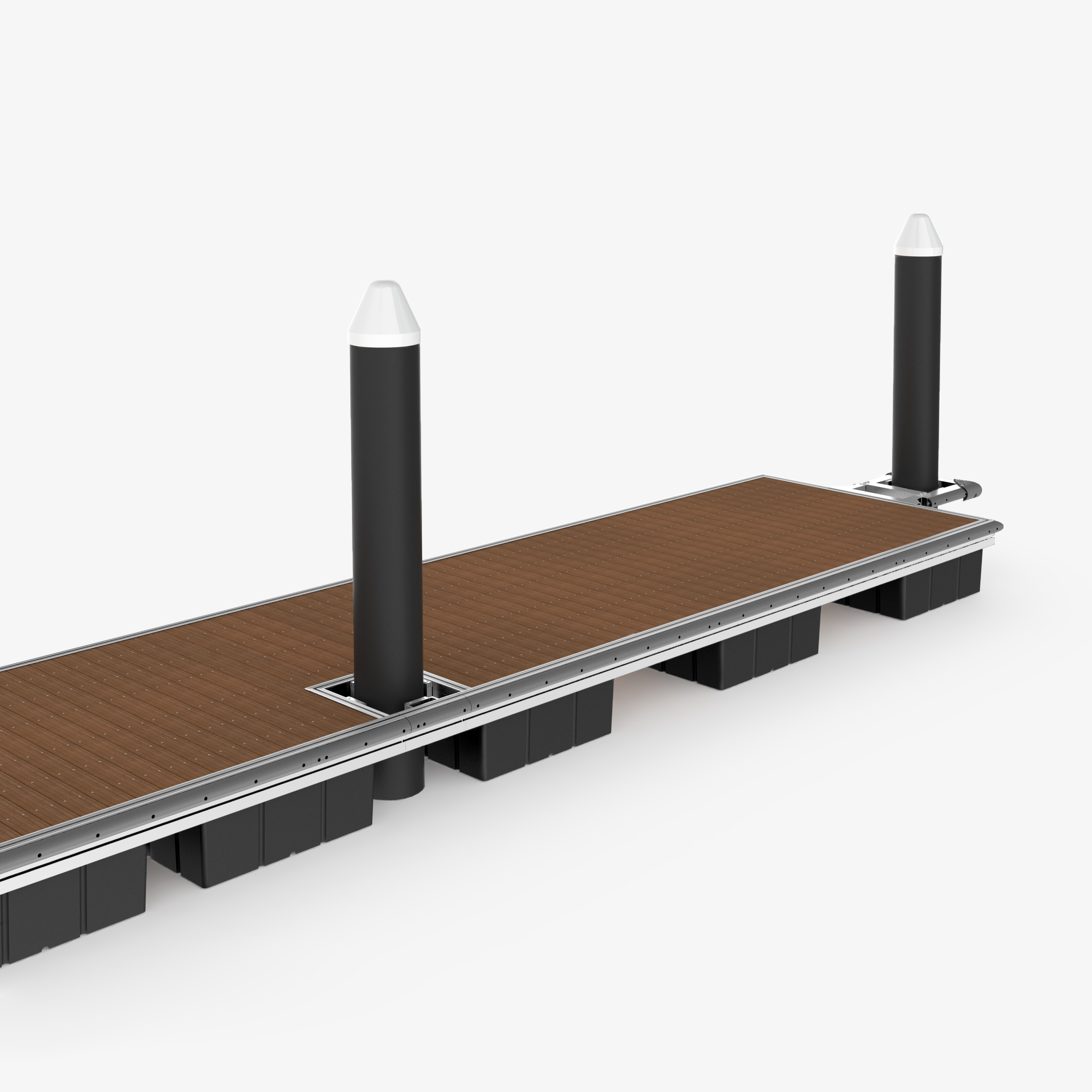

| Bollards | Single bitt: 15" – up to 4,250 lb (381 mm – up to 19 kN) |

Single bitt: 15" – up to 4,250 lb (381 mm – up to 19 kN) |

Double bitt: 15" – up to 14,400 lb (381 mm – up to 64 kN) |

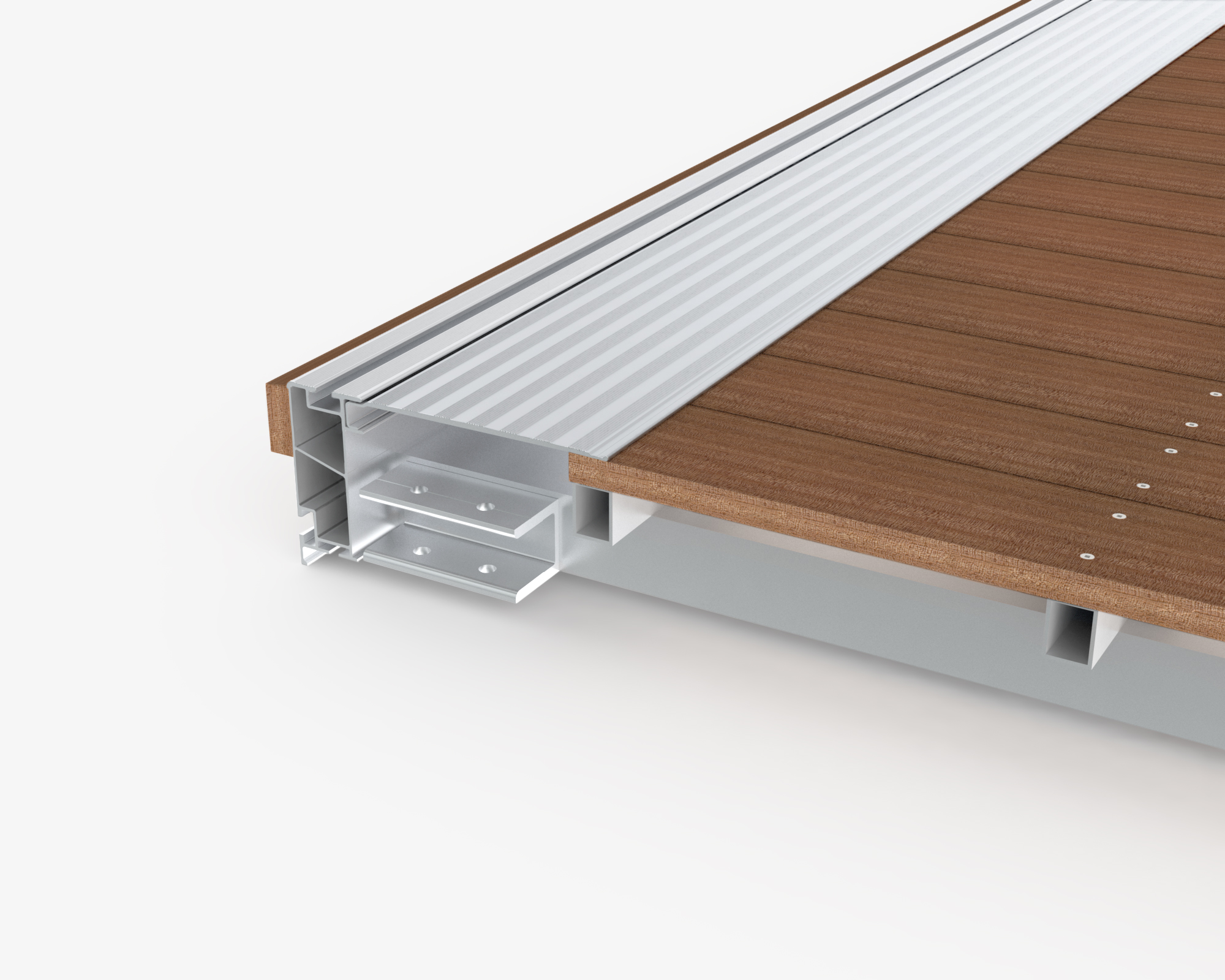

| Optional utility trough covers | 9" (229 mm) | Lateral: 9" (229 mm) Central: 16" (406 mm) |

Lateral: 12" (305 mm) Central: 16" (406 mm) |

| Multifunction track system | Single rail | Single rail | Double rail |

Expertise you can count on for floating docks

Speedy turnaround

We manufacture our aluminum docks and gangways right in our Canadian plant, eliminating the need to work with a separate supplier. Plus, our large inventory on hand prevents supply chain delays.

Experienced engineers

Alongside the hundreds of structural extruded aluminum projects MAADI Group has designed and built, we’ve earned numerous awards, including the Extrusion Technology Foundation’s Design Competition Award in the structural category—won for the third time in 2022. Our offerings include comprehensive engineering support for everything from bridges to floating boat docks, backed by in-house Registered Professional Engineers and a Certified Welding Engineer. All welding procedures meet the highest quality standards, ensuring safe, durable aluminum structures.

Built to code

All of our design specifications meet local, regional, and national building codes and professional standards as required. All of our technical designs and calculations for our aluminum marine structures bear the seal of one of our professional engineers.

Guaranteed quality

Backed by 12-year limited warranty on aluminum against material failure, defects, and corrosion

Marine Constructions

We’re your partner for a job well done, no matter how much (or how little) of our expertise you need. Our services include full engineering, technical support and manufacturing, planning, and installation.

See our Services

Documentation

Want more details? Download our technical information about our products. And feel free to contact us with any questions!

FAQs

What is a floating dock, and who is it best for?

A floating dock is a marine access structure supported by engineered flotation, allowing the dock system to rise and fall with changing water levels caused by tides, seasonal variations, or reservoir drawdowns. Unlike fixed docks, floating dock systems maintain consistent freeboard, ensuring safe and accessible boarding conditions regardless of water elevation.

Floating docks are particularly wellsuited for marinas, yacht clubs, resorts, municipal harbors, ferry terminals, and urban waterfront developments, as well as highend residential waterfronts. They provide stable, level access to vessels, accommodate a wide range of boat sizes, and integrate seamlessly with gangways, wave attenuators, utilities, and mooring systems.

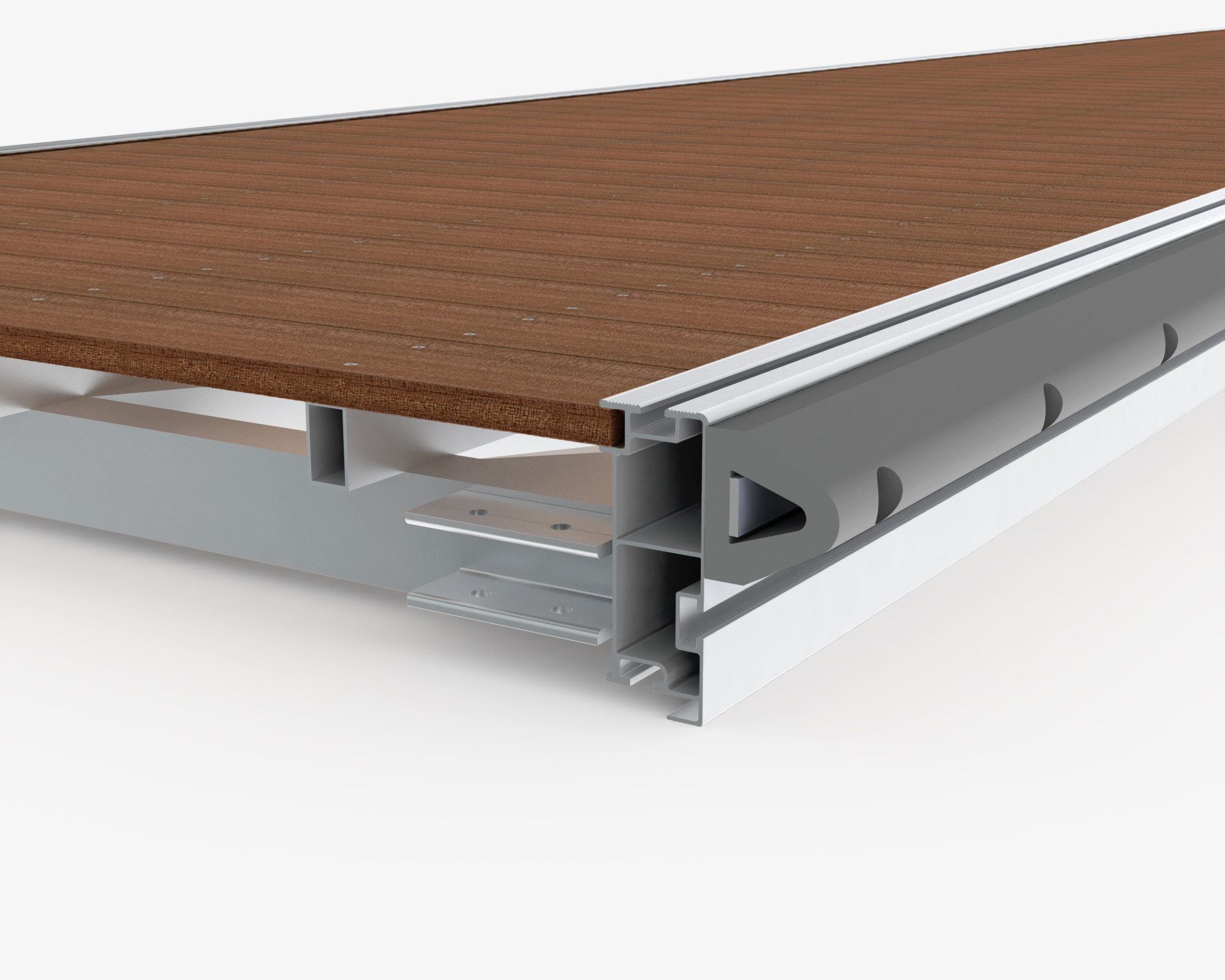

When properly engineered, floating dock systems are designed to resist wind, wave action, ice forces, live loads, and longterm environmental exposure, while minimizing maintenance over their service life. Materials such as marinegrade aluminum framing and durable flotation systems make floating docks an ideal solution for projects requiring longevity, adaptability, and a clean, professional aesthetic.

Do you build custom floating docks to fit my waterfront and boat size?

Yes. MAADI Group designs and manufactures fully custom floating dock systems engineered to match your shoreline conditions, marina layout, slip configuration, and vessel mix. Each dock system is tailored to your waterfront geometry, water depth, and environmental exposure, accommodating everything from small recreational craft to larger commercial vessels and superyachts.

Our engineering team works closely with you during the design phase to optimize dock sizing, freeboard, structural capacity, mooring strategy, and access geometry, ensuring safe, efficient, and longterm performance. Sitespecific factors such as wind, wave action, ice loads, utilities integration, and operational traffic are fully incorporated into the engineering process.

MAADI Group offers three distinct floating dock systems, each engineered for specific vessel sizes and environmental demands:

- Tri Ocean™ — designed for large vessels and highenergy marine environments

- Great Lakes™ — engineered for heavy saltwater or freshwater conditions and variable water levels

- Lakeshore™ — optimized for protected waters and recreational applications

Our floating dock systems can be customized with a wide range of finishes and functional features, including:

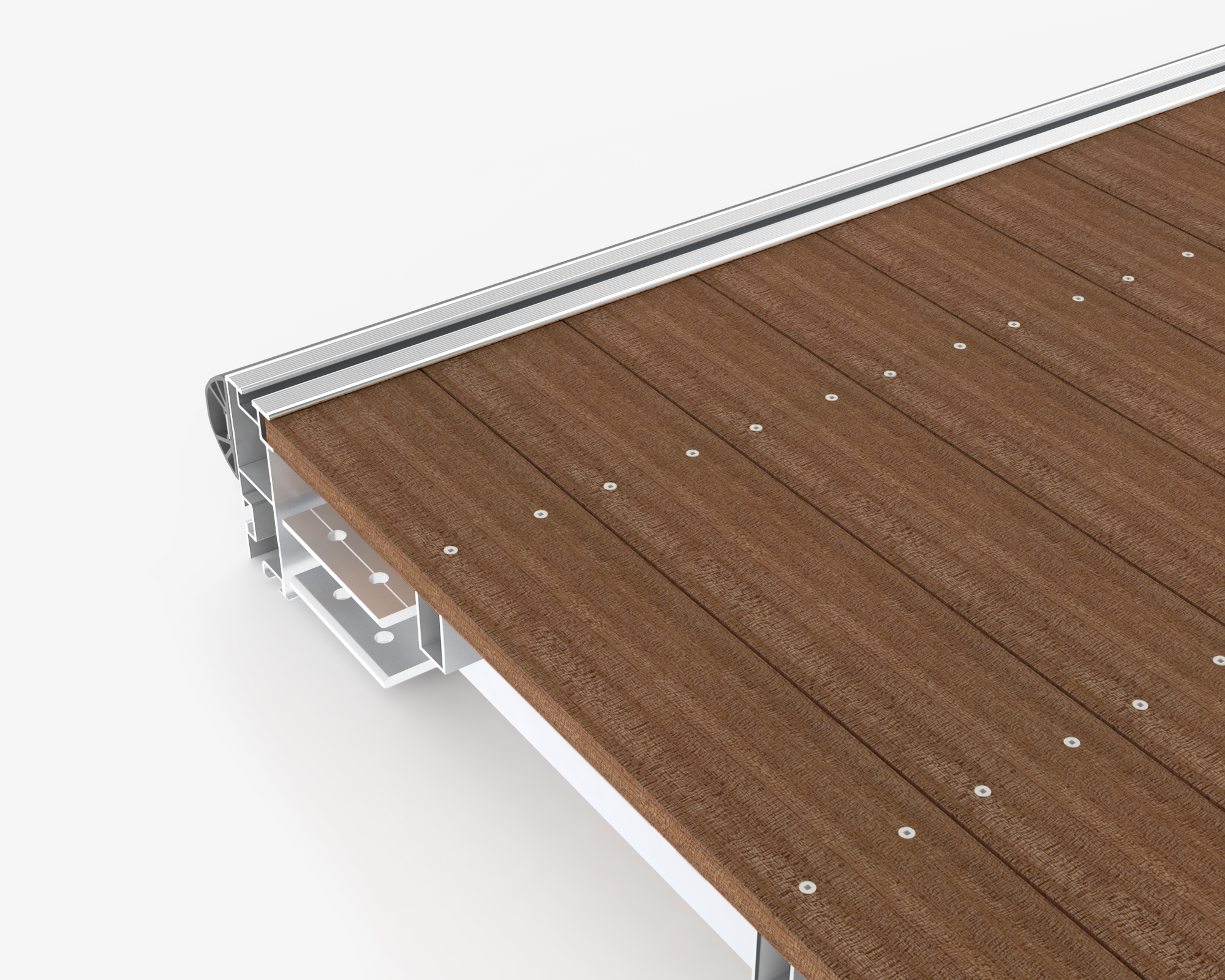

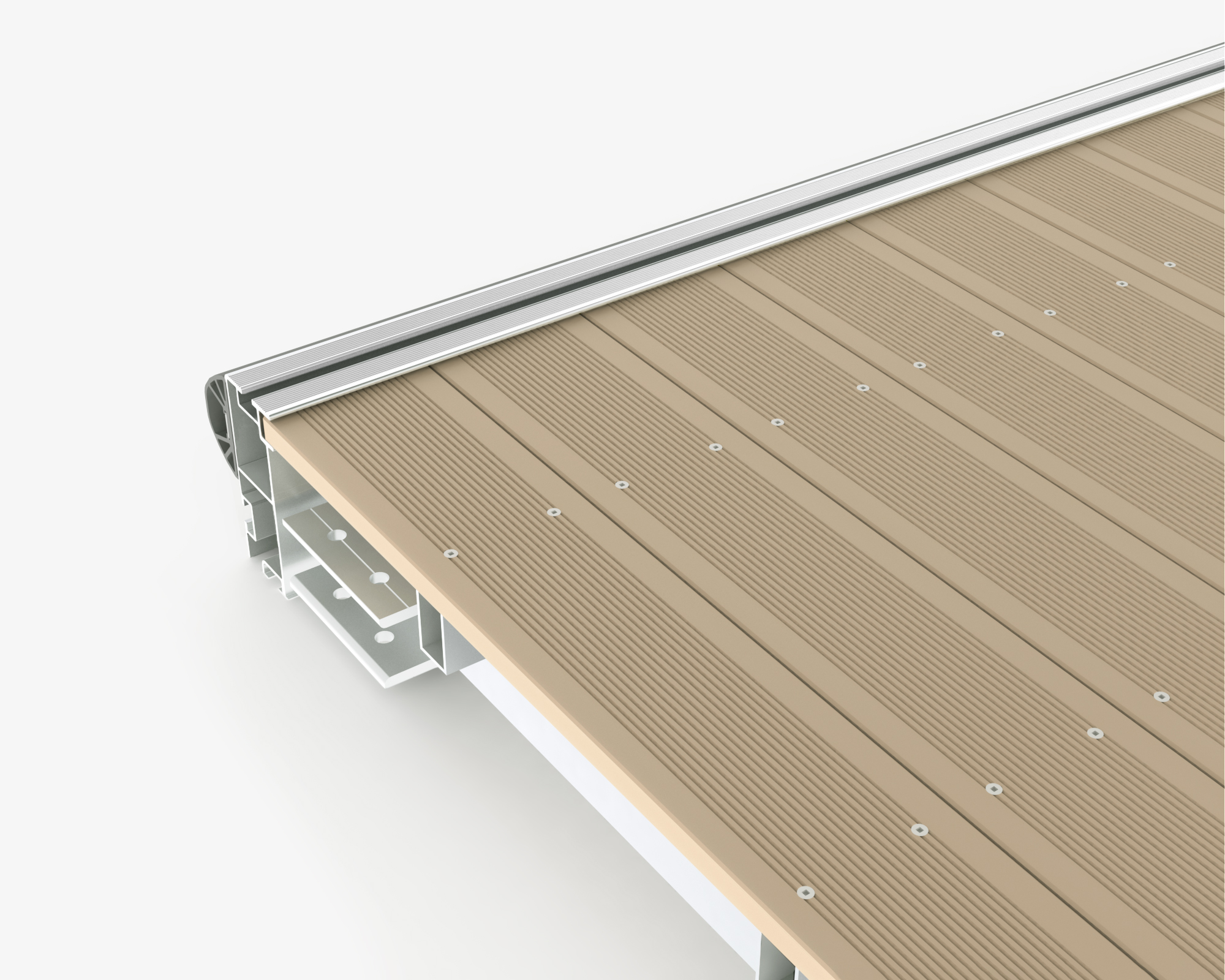

- Decking systems (composite, aluminum, exotic hardwoods, or specialty surfaces)

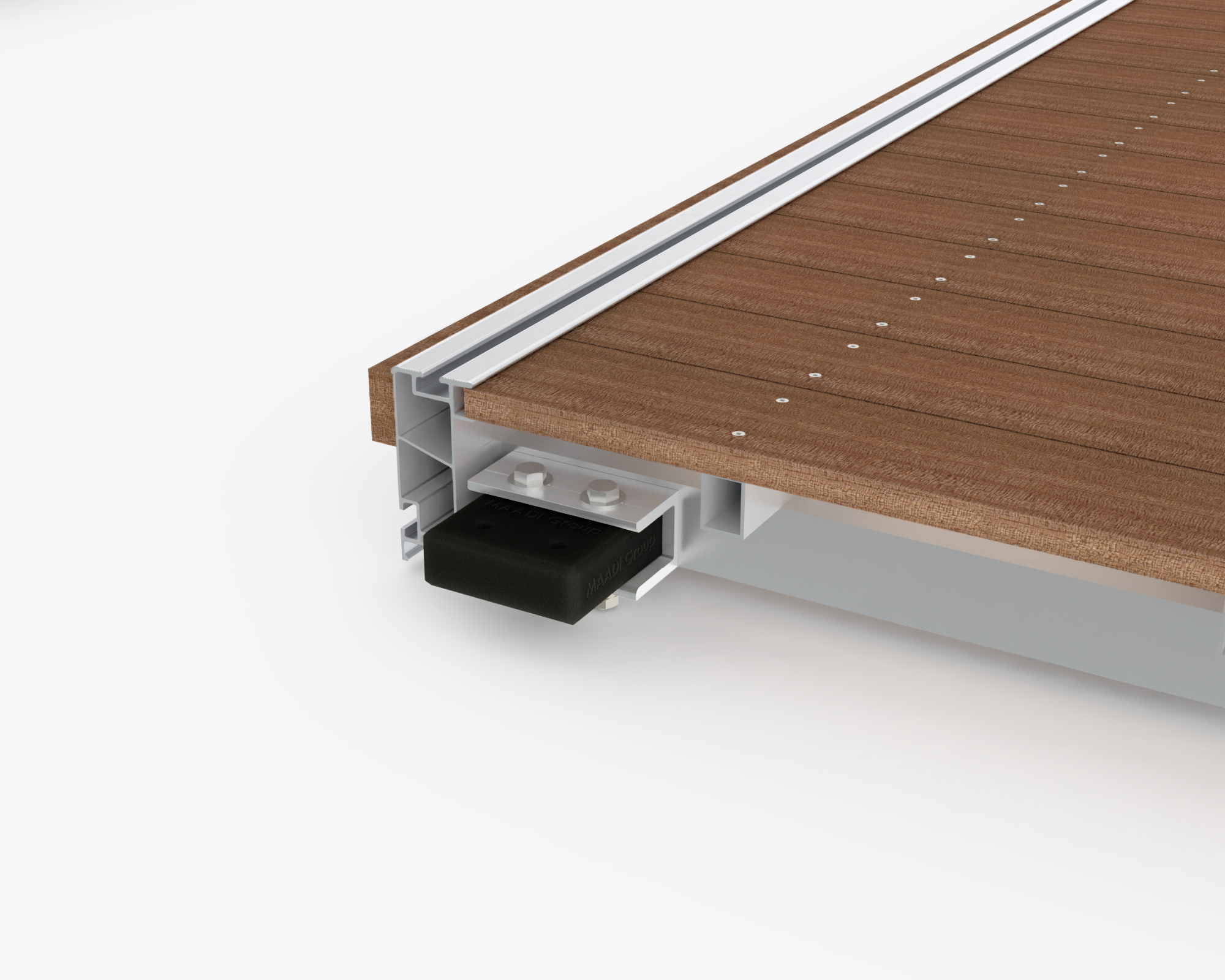

- Integrated or external piles and pileguide systems, including ShockGUARD™ energyabsorbing technology to protect longterm infrastructure

- Fender systems for small craft, large vessels, or commercial operations

- Cleats, bollards, and mooring hardware sized for design vessel loads

- Integrated LED lighting for safety, visibility, and aesthetics

- Clearanodized, highend MakeABridge™ gangways or welded aluminum Gangways

- Utility trough covers and hatch systems, including concealed fuel dock Infrastructure

- Additional marina accessories tailored to operational requirements

Each custom floating dock system is engineered, fabricated, and qualitycontrolled in Canada, delivering a solution that combines precision engineering, durability, and a clean, professional marina appearance—built to perform reliably for decades.

Why choose an aluminum floating dock instead of wood or plastic?

An aluminum floating dock is a longterm marine infrastructure solution engineered for durability, structural performance, and low lifecycle cost in demanding waterfront environments. Compared to wood, steel, concrete, or plastic systems, aluminum floating docks offer a superior balance of strength, corrosion resistance, adaptability, and minimal maintenance.

Superior Corrosion Resistance in Marine Environments

Marinegrade aluminum naturally forms a protective oxide layer that provides excellent resistance to corrosion in saltwater, brackish water, and freshwater environments. Unlike steel, aluminum does not rely on heavy coatings or cathodic protection systems to achieve long service life, making it especially wellsuited for coastal marinas, harbors, and waterfront infrastructure.

Structural Strength Without Excess Weight

Compared to plastic dock systems, aluminum provides a rigid, engineered structural frame capable of supporting higher live loads, vessel berthing forces, and sustained heavy foot & kart traffic. At the same time, aluminum is significantly lighter than steel or concrete, reducing overall system mass without compromising strength.

This lower weight and favorable strengthtomass ratio result in reduced inertia loads, which is particularly beneficial in highenergy and hurricaneprone environments. Unlike concrete, aluminum structures respond more flexibly to dynamic forces, helping to preserve pile anchoring systems, connections, and overall structural behavior during extreme wind and wave events.

The reduced structural mass also lowers flotation requirements, improves dock responsiveness to wave action, and simplifies installation, relocation, and future system expansion—making aluminum floating docks a superior solution for both performancecritical and longterm marina infrastructure.

Reduced Maintenance Compared to Wood

Wood docks are susceptible to rot, warping, splitting, insect damage, and frequent refinishing, particularly in wet or freezethaw climates. Aluminum floating docks eliminate these failure modes entirely, resulting in lower maintenance costs, improved safety, and longer replacement intervals over the life of the dock system.

Design Flexibility and LongTerm Adaptability

Aluminum floating docks are modular by design, allowing systems to be expanded, reconfigured, or relocated as marina layouts, vessel sizes, or operational needs evolve. This level of flexibility is difficult to achieve with concrete docks and far more structurally reliable than many plastic systems when scaling for larger vessels or commercial Operations.

In addition, the aluminum extrusion process enables advanced structural features that are not achievable with other materials. These include integrated track systems that allow easy repositioning of accessories such as cleats, bollards, ladders, and external pile guides, as well as internal service chases, inspection ports, portholes, and variable wall thickness in highstress regions—optimizing structural performance exactly where it is required.

Engineered for Performance and Longevity

When properly engineered, aluminum floating docks are designed to withstand wind and wave loads, ice forces, vessel impact loads, and continuous environmental exposure. The result is a dock system with predictable structural behavior, long service life, and a clean, professional appearance that enhances both operational performance and asset value.

Can your floating docks be expanded later if I need more space?

Yes. MAADI Group’s floating dock systems are modular and can be reconfigured, which makes it easy to add sections, extend walkways, or adjust the layout as your waterfront needs grow.

Do you deliver and install floating docks, or do I need my own installer?

You’ve got options. MAADI Group can ship dock sections assembled on a trailer or deliver them in containers for on-site assembly. Installation can be handled by your local contractor with MAADI Group supervision, or by MAADI Group’s certified installers, and inspections can be completed by their professional engineers to confirm compliance and safety.

Are your floating docks suitable for lakes, rivers, and saltwater?

Yes. MAADI Group designs aluminum floating docks for both commercial and residential waterfronts, and the systems are built with marine‑grade aluminum made to resist corrosion from salt water, chemicals, and pollution. In other words, whether you’re on a calm lake, a moving river, or a coastal marina, the dock can be engineered to suit the conditions.

What maintenance do aluminum floating docks typically need?

Aluminum floating docks are a low-maintenance option. MAADI Group notes their aluminum floating docks require far less maintenance than steel, and their FAQ also highlights that well-designed, well-maintained aluminum floating docks can last 40+ years. In most cases, “maintenance” looks like routine inspections, cleaning the deck, checking hardware and accessories, and (in saltwater) rinsing and keeping an eye on high-wear contact points.

What accessories can I add (ladders, cleats, bumpers, benches, etc.)?

MAADI Group floating dock systems can be fully customized with a wide range of functional accessories and comfort features to match your operational requirements, vessel types, and aesthetic objectives.

Common floating dock accessories include:

- Decking options to achieve the desired appearance, durability, and performance (composite, aluminum, or specialty finishes)

- Cleats, bollards, and mooring hardware sized for secure and reliable vessel tie-ups

- Fender and bumper systems to protect boats, dock edges, and structural components

- Dock ladders for safe swimmer access and emergency egress

- Utility trough covers to protect and discreetly route electrical, water, and fuel services

- Integrated LED lighting systems for safety, visibility, and nighttime ambiance

- Hatch covers to conceal under-dock equipment such as fuel pump and utility systems

- Clear-anodized, high-end aluminum gangways engineered for long-term durability and refined aesthetics

For public marinas, resorts, and high-end waterfront developments, dock layouts can also incorporate custom furnishings such as benches, planters, seating areas, canopied and commercial-grade umbrellas, as well as architectural lighting systems that enhance both functionality and the overall waterfront experience.

All accessories are engineered to integrate seamlessly with MAADI Group’s aluminum dock systems, ensuring structural compatibility, long-term durability, and a clean, professional appearance across the entire marina or waterfront installation.

Download your resource

"*" indicates required fields